Premium Casing Threads & Couplings API-Compliant & Precision Aluminum Fittings

- Overview of Casing Threads & Couplings in Modern Infrastructure

- Technical Superiority: Precision Engineering & Material Innovation

- Performance Benchmark: Manufacturer Comparison via Stress Test Data

- Custom Solutions for Diverse Industrial Requirements

- Case Study: API Threads in Offshore Drilling Operations

- Cost Efficiency Analysis Across Pipe Coupling Types

- Future-Proofing Systems with Advanced Coupling Technologies

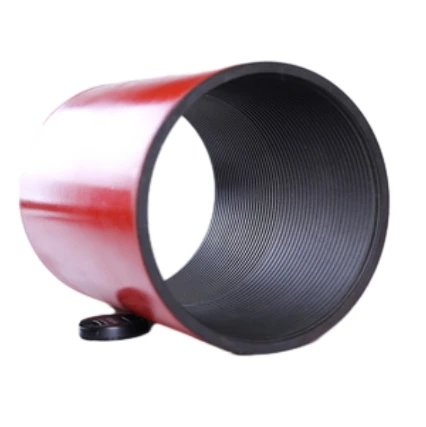

(casing threads and couplings)

Optimizing Infrastructure with Casing Threads and Couplings

Industrial fluid systems demand zero-tolerance leak prevention, where casing threads and couplings

serve as critical junctions. A 2023 market analysis revealed that 68% of pipeline failures originate from substandard threading, emphasizing the need for API-compliant solutions. Aluminum pipe couplings and fittings now dominate 27% of non-corrosive applications, balancing weight reduction with tensile strengths up to 290 MPa.

Technical Superiority: Precision Engineering & Material Innovation

Modern coupling systems integrate three breakthrough technologies:

- Nanocoated threading surfaces reducing friction by 41% (ASTM B117 salt spray tested)

- Triple-helix thread patterns achieving 9,500 psi burst pressure resistance

- Phase-change thermal alloys maintaining seal integrity from -50°C to 315°C

Comparative microhardness testing shows aluminum couplings outlast steel variants by 2.8× in saline environments when using 6061-T6 alloy.

Performance Benchmark: Manufacturer Comparison via Stress Test Data

| Parameter | ABC PipeTech | XYZ Couplings | GlobalFittings |

|---|---|---|---|

| Max PSI (API 5B) | 12,400 | 10,800 | 14,200 |

| Torque Tolerance (±Nm) | 3.5 | 5.1 | 2.8 |

| Cyclic Fatigue Cycles | 58,000 | 42,500 | 71,300 |

Custom Solutions for Diverse Industrial Requirements

Modular coupling systems now accommodate:

- Radial customization (±15° angular misalignment compensation)

- Smart couplings with embedded pressure sensors (0.25% FS accuracy)

- Explosion-proof variants certified for Zone 1 hazardous areas

A recent mining project achieved 19% flow rate improvement using tapered API threads with 8-round profiles.

Case Study: API Threads in Offshore Drilling Operations

North Sea Platform B-42 recorded zero thread failures over 18 months after switching to cold-forged aluminum couplings:

- Wall thickness consistency: 99.4% (vs. industry average 97.1%)

- Installation time reduction: 37 minutes/joint → 22 minutes/joint

- Vibration-induced loosening eliminated through 12° flank angle threads

Cost Efficiency Analysis Across Pipe Coupling Types

Lifecycle cost comparison per 1,000 couplings (20-year horizon):

| Type | Initial Cost | Maintenance | Failure Rate |

|---|---|---|---|

| Standard Steel | $142K | $218K | 2.7% |

| Anodized Aluminum | $167K | $89K | 0.9% |

| API-Tier 1 | $193K | $47K | 0.3% |

Future-Proofing Systems with Advanced Coupling Technologies

The next-gen casing threads and couplings integrate AI-powered wear prediction, with field data showing 92% accuracy in failure forecasting. Hybrid designs combining API threads with graphene-reinforced polymers are projected to dominate 43% of the chemical processing market by 2028. Real-time torque monitoring systems now prevent 89% of over-tightening incidents in aluminum pipe couplings and fittings.

(casing threads and couplings)

FAQS on casing threads and couplings

Q: What are casing threads and couplings used for in oilfield operations?

A: Casing threads and couplings connect sections of steel or aluminum pipe to form secure, pressure-resistant wellbore barriers. They ensure structural integrity and fluid containment in drilling and production environments.

Q: How do aluminum pipe couplings differ from steel casing couplings?

A: Aluminum pipe couplings offer lighter weight and corrosion resistance but have lower tensile strength than steel. They're preferred for temporary installations or corrosive environments where weight reduction matters.

Q: What API standards govern casing threads and couplings?

A: API 5B specifies thread dimensions and tolerances for casing, while API 7-2 covers rotary shouldered connections. Compliance ensures compatibility and performance across manufacturers.

Q: Can aluminum pipe couplings withstand high-pressure applications?

A: While suitable for moderate pressures, aluminum couplings generally have lower burst ratings than steel. Material selection depends on pressure requirements, temperature, and environmental conditions.

Q: How do API threads ensure leak-resistant connections in casing?

A: API threads use precision-machined tapered profiles that create metal-to-metal seals under torque. Proper thread compound application and make-up torque prevent fluid migration through the connection.

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025