- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

មករា . 20, 2025 11:07

Back to list

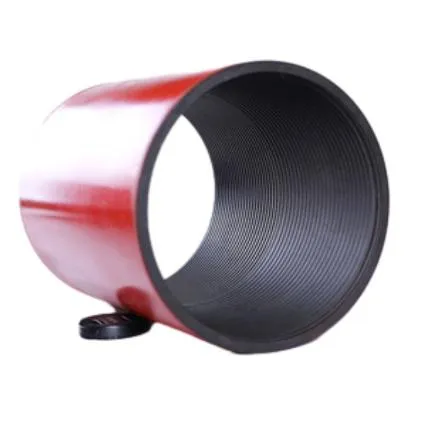

casing coupling china manufacturer

Navigating the intricate world of plumbing and fluid transfer systems can be challenging, especially when one begins to delve into the myriad of components that make these systems function seamlessly. Among these components, coupling tube fittings hold a pivotal role, ensuring a secure and efficient connection between tubes while maintaining system integrity. This article delves into the nuances of coupling tube fittings, offering insights and tips from seasoned industry experts to inform and guide your purchasing decisions.

Expert consultations often emphasize the importance of matching the size of the fitting with the tube diameter precisely. This precision ensures that there are no weak spots in the assembly that could lead to leaks. In complex applications, such as those found in chemical processing plants or hydraulic systems, even the smallest misalignment can lead to significant inefficiencies or hazards. Authoritativeness in the industry also dictates that one should not overlook the standards and certifications that come with these components. Coupling tube fittings should comply with international standards, such as those set by ISO or ASME, to ensure they meet safety and performance metrics required for specific applications. Purchasing decisions should also be influenced by the reputation and credibility of the manufacturer. Companies with established track records and stringent quality control measures often provide products with higher reliability. Case studies and user testimonials can be valuable, offering insights into real-world performance and longevity. Lastly, as an expert tip, always consider future scalability when investing in coupling tube fittings. As systems grow or change, the flexibility to adapt fittings to new configurations without requiring entire system overhauls can save time and resources. In conclusion, while coupling tube fittings may appear to be mere connectors within a larger system, their role is crucial. By prioritizing material compatibility, precise sizing, design suitability, and adherence to industry standards, one can ensure that their fluid transfer systems operate efficiently and safely. Trust in expert advice and credible manufacturers cannot be overstated, and these components are indeed worthy of careful consideration and investment.

Expert consultations often emphasize the importance of matching the size of the fitting with the tube diameter precisely. This precision ensures that there are no weak spots in the assembly that could lead to leaks. In complex applications, such as those found in chemical processing plants or hydraulic systems, even the smallest misalignment can lead to significant inefficiencies or hazards. Authoritativeness in the industry also dictates that one should not overlook the standards and certifications that come with these components. Coupling tube fittings should comply with international standards, such as those set by ISO or ASME, to ensure they meet safety and performance metrics required for specific applications. Purchasing decisions should also be influenced by the reputation and credibility of the manufacturer. Companies with established track records and stringent quality control measures often provide products with higher reliability. Case studies and user testimonials can be valuable, offering insights into real-world performance and longevity. Lastly, as an expert tip, always consider future scalability when investing in coupling tube fittings. As systems grow or change, the flexibility to adapt fittings to new configurations without requiring entire system overhauls can save time and resources. In conclusion, while coupling tube fittings may appear to be mere connectors within a larger system, their role is crucial. By prioritizing material compatibility, precise sizing, design suitability, and adherence to industry standards, one can ensure that their fluid transfer systems operate efficiently and safely. Trust in expert advice and credible manufacturers cannot be overstated, and these components are indeed worthy of careful consideration and investment.

Next:

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products