Feb . 19, 2025 09:51

Back to list

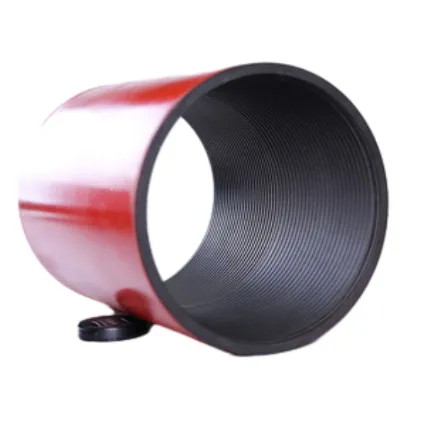

pump seating nipple

Pump seating nipples are a quintessential element in the realm of well completion and pump installation, often playing a decisive role in the efficiency and reliability of downhole operations. Despite their seemingly simple design, the expertise behind their application ensures smooth functionality and operational credibility, anchoring their place as indispensable components in various industrial sectors.

The authority of pump seating nipples in industry applications is not solely derived from their engineering precision but also from the credibility they maintain in operational settings. Products passed through rigorous quality checks and testing protocols provide an assurance of performance, reinforcing their standing as a trustable solution across global operations. Regulatory standards foster a framework within which these components operate, thereby guaranteeing compliance with safety and efficiency norms that lead to optimized extraction processes. A confluence of innovation, practical experience, and stringent quality assurance underlines the unmatched reliability of pump seating nipples. Their application transcends beyond mere mechanical function; they are pivotal in sustaining operational integrity, enabling industries to meet their productivity benchmarks effortlessly. In summary, the pump seating nipple embodies the synthesis of engineering finesse and application expertise, offering a reliability quotient that is unrivaled within the scope of high-pressure extraction and other industrial applications. By embedding trust, authority, and professionalism, these tools stand as a beacon of efficiency, assuring industries of ongoing, smooth operations underpinned by the finest in mechanical engineering design.

The authority of pump seating nipples in industry applications is not solely derived from their engineering precision but also from the credibility they maintain in operational settings. Products passed through rigorous quality checks and testing protocols provide an assurance of performance, reinforcing their standing as a trustable solution across global operations. Regulatory standards foster a framework within which these components operate, thereby guaranteeing compliance with safety and efficiency norms that lead to optimized extraction processes. A confluence of innovation, practical experience, and stringent quality assurance underlines the unmatched reliability of pump seating nipples. Their application transcends beyond mere mechanical function; they are pivotal in sustaining operational integrity, enabling industries to meet their productivity benchmarks effortlessly. In summary, the pump seating nipple embodies the synthesis of engineering finesse and application expertise, offering a reliability quotient that is unrivaled within the scope of high-pressure extraction and other industrial applications. By embedding trust, authority, and professionalism, these tools stand as a beacon of efficiency, assuring industries of ongoing, smooth operations underpinned by the finest in mechanical engineering design.

Next:

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products