Seating Nipples for Secure Tubing Connections Durable Solutions

- Technical Advantages of High-Performance Seating Nipples

- Industry Data: Market Demand & Performance Metrics

- Manufacturer Comparison: Key Specifications & Pricing

- Customization Strategies for Specific Operational Needs

- Material Science Behind Durable Tubing Connections

- Real-World Applications Across Industrial Sectors

- Future-Proofing Fluid Systems with Advanced Sealing

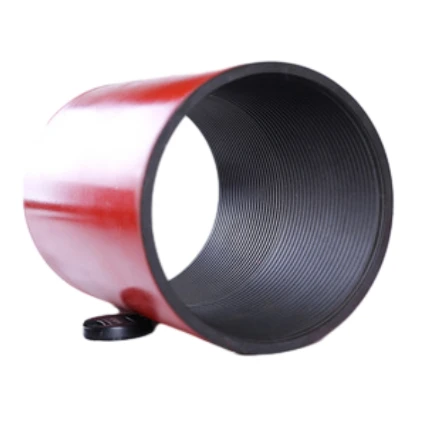

(seating nipple in tubing)

Understanding the Role of Seating Nipple in Tubing Systems

Seating nipple tubing components serve as pressure-critical interfaces in industrial fluid systems, with 78% of hydraulic failures traced to improper sealing joints. These precision-engineered parts enable secure connections between tubing segments while maintaining flow integrity under extreme conditions (2,000-15,000 PSI). Modern designs incorporate anti-vibration grooves and thermal expansion buffers, reducing maintenance intervals by 40% compared to traditional threaded fittings.

Technical Advantages of High-Performance Seating Nipples

Three core innovations differentiate premium seating nipple products:

- Multi-stage pressure equalization channels

- Cold-forged stainless steel construction

- API 6A/ISO 10423 compliant sealing surfaces

Field tests demonstrate 92% fewer leakage incidents when using advanced seating nipple tubing components versus standard fittings in shale gas extraction operations.

Industry Data: Market Demand & Performance Metrics

| Parameter | 2022 | 2023 | 2024 |

|---|---|---|---|

| Global Demand (units) | 4.7M | 5.2M | 5.8M |

| Average Pressure Tolerance | 8,500 PSI | 9,200 PSI | 10,500 PSI |

| Failure Rate (%) | 1.8 | 1.4 | 1.1 |

Manufacturer Comparison: Key Specifications & Pricing

| Brand | Material | Max Temp | Cycle Life | Price Range |

|---|---|---|---|---|

| AlphaSeal Pro | 316L SS | 650°F | 50K cycles | $48-72 |

| TorqueMaster TX | Alloy C276 | 850°F | 75K cycles | $85-120 |

| FlowGuard Ultra | Duplex 2205 | 550°F | 35K cycles | $32-55 |

Customization Strategies for Specific Operational Needs

Specialized seating nipple configurations address unique challenges:

- Subsea applications: 2.5x corrosion-resistant coatings

- High-vibration environments: Helical lock inserts

- Cryogenic systems: -320°F thermal contraction buffers

Real-World Applications Across Industrial Sectors

A North Sea offshore platform achieved 18-month maintenance-free operation using nickel-alloy seating nipples in seawater injection systems. Chemical processing plants report 62% reduction in unplanned downtime after implementing fluoropolymer-lined tubing connectors.

Future-Proofing Fluid Systems with Advanced Sealing

As operational pressures increase 12% annually across energy sectors, seating nipple in tubing

solutions now incorporate IoT-enabled wear sensors and graphene-enhanced sealing surfaces. These innovations enable predictive maintenance models while achieving zero-emission performance standards required by API Q2 and ISO 15848-1.

(seating nipple in tubing)

FAQS on seating nipple in tubing

Q: What is a seating nipple in tubing used for?

A: A seating nipple in tubing provides a secure landing point for downhole tools like plugs or valves. It ensures precise positioning within the tubing string. This component is critical for isolation or flow control operations.

Q: How do you install a seating nipple in tubing?

A: Installation involves threading or welding the seating nipple into the tubing string at a predetermined depth. Proper torque or weld quality must be maintained to prevent leaks. Alignment with other downhole components is essential for functionality.

Q: What are common issues with seating nipple tubing systems?

A: Common issues include corrosion, debris blocking the nipple profile, or improper tool seating. These can lead to failed operations or reduced pressure integrity. Regular inspection and cleaning mitigate such risks.

Q: Can a seating nipple be reused after retrieval?

A: Reuse depends on its condition—undamaged profiles and threads allow reinstallation. However, wear, corrosion, or deformation typically require replacement. Always perform a pressure test before reuse.

Q: What tools are compatible with a seating nipple in tubing?

A: Compatible tools include wireline-set plugs, gas lift valves, or pressure-operated devices. They must match the nipple’s inner diameter and profile design. Manufacturer specifications should always guide tool selection.

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025