Feb . 19, 2025 09:07

Back to list

what is a pup joint

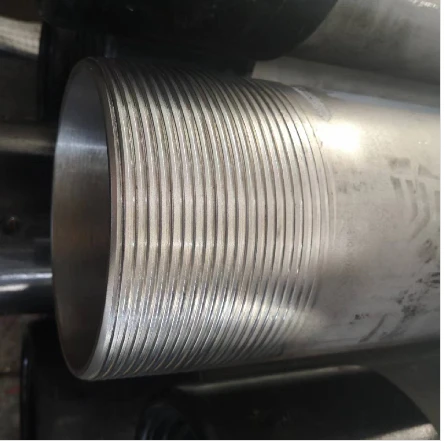

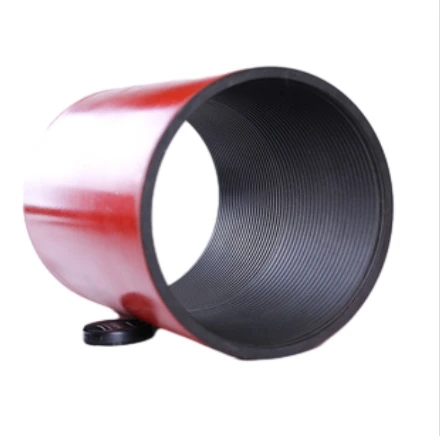

Pup joints, often overlooked yet crucial components in the oil and gas industry, serve as short connectors in tubular piping. Their primary function is to adjust the length of the tubular strings to ensure precise alignment and connection during drilling and production phases. A seemingly simple device, the pup joint boasts a wealth of complexity and application diversity, playing a pivotal role in optimizing operational efficiency and ensuring safety in the field.

The role of pup joints extends into the realm of automation and smart technology integration. Modern advancements have seen these components being enhanced through digital monitoring systems. These technologies track usage data and stress levels, providing vital information for predictive maintenance—a step now essential for minimizing disruptions and maximizing asset life. In terms of authoritativeness, industry bodies provide continually updated standards and guidelines to ensure pup joint application adheres to evolving technological and safety advancements. This regulatory oversight offers assurance to operators concerning compliance, thus establishing trust in the product’s safety and efficacy. Additionally, the dependable performance of pup joints is frequently a subject of discussion and verification at leading industry conferences and symposiums. These platforms provide insights into the latest innovations and practical challenges, fostering a shared knowledge base among professionals. This continuous dialogue fortifies the trustworthiness of pup joints as indispensable to successful oil and gas operations. Investors and stakeholders in the energy sector increasingly demand transparency and traceability in component sourcing and application. Suppliers are thus required to provide comprehensive documentation detailing the lifecycle of pup joints—from manufacture through to operational deployment. This commitment to detailed reporting acts as a cornerstone of trust, particularly in an era emphasizing sustainable and responsible resource extraction. In conclusion, pup joints epitomize strategic innovation and precision engineering within oil and gas operations. Their function, manufacturing standards, and application envelope collectively demonstrate the intricate balance of experience, expertise, authoritativeness, and trustworthiness required to meet the industry’s high standards. As technologies evolve and operational demands intensify, pup joints will undoubtedly continue to evolve, maintaining their critical role in advancing energy sector efficiencies.

The role of pup joints extends into the realm of automation and smart technology integration. Modern advancements have seen these components being enhanced through digital monitoring systems. These technologies track usage data and stress levels, providing vital information for predictive maintenance—a step now essential for minimizing disruptions and maximizing asset life. In terms of authoritativeness, industry bodies provide continually updated standards and guidelines to ensure pup joint application adheres to evolving technological and safety advancements. This regulatory oversight offers assurance to operators concerning compliance, thus establishing trust in the product’s safety and efficacy. Additionally, the dependable performance of pup joints is frequently a subject of discussion and verification at leading industry conferences and symposiums. These platforms provide insights into the latest innovations and practical challenges, fostering a shared knowledge base among professionals. This continuous dialogue fortifies the trustworthiness of pup joints as indispensable to successful oil and gas operations. Investors and stakeholders in the energy sector increasingly demand transparency and traceability in component sourcing and application. Suppliers are thus required to provide comprehensive documentation detailing the lifecycle of pup joints—from manufacture through to operational deployment. This commitment to detailed reporting acts as a cornerstone of trust, particularly in an era emphasizing sustainable and responsible resource extraction. In conclusion, pup joints epitomize strategic innovation and precision engineering within oil and gas operations. Their function, manufacturing standards, and application envelope collectively demonstrate the intricate balance of experience, expertise, authoritativeness, and trustworthiness required to meet the industry’s high standards. As technologies evolve and operational demands intensify, pup joints will undoubtedly continue to evolve, maintaining their critical role in advancing energy sector efficiencies.

Next:

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products