Feb . 14, 2025 06:27

Back to list

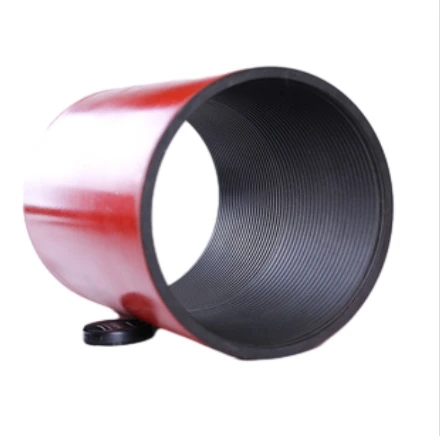

seating nipple tubing

In the intricate world of the oil and gas industry, precision is key. Every component plays a pivotal role in ensuring that the entire system functions seamlessly and effectively. Among these vital components, the seating nipple tubing stands out as a critical element designed to deliver both efficiency and reliability in wellbore completion systems.

For the field professionals using seating nipple tubing, understanding the exact specifications and operational limits is crucial. Expertise in installation and maintenance practices can significantly enhance the longevity and functionality of this equipment. Training in best practices ensures that seating nipple tubing is installed correctly, providing a tight seal that prevents leakages and ensures optimal performance. Incorporating advanced technology in the monitoring and analysis of seating nipple tubing also positions operators to prevent potential failures and optimize performance. Sensors and data analytics offer insights into pressures and flow rates, enabling a proactive approach to maintenance and troubleshooting. This integration of technology not only enhances operational efficiency but also elevates safety standards across oil and gas operations. Trustworthiness and reliability of seating nipple tubing are further underscored by rigorous testing and certification processes. Each component undergoes meticulous quality assurance to meet industry standards and regulatory requirements. This thorough verification process ensures that only the highest quality products make it to market, providing operators with the confidence needed to execute critical operations without the fear of equipment malfunction. In conclusion, seating nipple tubing is more than just a component in the wellbore; it is a cornerstone of effective and efficient oil and gas operations. The combination of robust material, precise engineering, expert installation, and continuous technological enhancement forms the foundation of its operational excellence. This expertise-driven approach ensures that seating nipple tubing remains a trustworthy element in the tapestry of subterranean exploration and production activities. Embracing these components with a focus on quality, precision, and innovation guarantees a strong framework for any successful oil and gas venture.

For the field professionals using seating nipple tubing, understanding the exact specifications and operational limits is crucial. Expertise in installation and maintenance practices can significantly enhance the longevity and functionality of this equipment. Training in best practices ensures that seating nipple tubing is installed correctly, providing a tight seal that prevents leakages and ensures optimal performance. Incorporating advanced technology in the monitoring and analysis of seating nipple tubing also positions operators to prevent potential failures and optimize performance. Sensors and data analytics offer insights into pressures and flow rates, enabling a proactive approach to maintenance and troubleshooting. This integration of technology not only enhances operational efficiency but also elevates safety standards across oil and gas operations. Trustworthiness and reliability of seating nipple tubing are further underscored by rigorous testing and certification processes. Each component undergoes meticulous quality assurance to meet industry standards and regulatory requirements. This thorough verification process ensures that only the highest quality products make it to market, providing operators with the confidence needed to execute critical operations without the fear of equipment malfunction. In conclusion, seating nipple tubing is more than just a component in the wellbore; it is a cornerstone of effective and efficient oil and gas operations. The combination of robust material, precise engineering, expert installation, and continuous technological enhancement forms the foundation of its operational excellence. This expertise-driven approach ensures that seating nipple tubing remains a trustworthy element in the tapestry of subterranean exploration and production activities. Embracing these components with a focus on quality, precision, and innovation guarantees a strong framework for any successful oil and gas venture.

Next:

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products