Pup Joint Specifications Schlumberger-Certified Oilfield Components

- Introduction to pup joint specifications

in modern drilling operations - Technical standards and material requirements

- Performance comparison: Schlumberger vs. industry competitors

- Custom engineering solutions for diverse operational needs

- Field applications and operational success metrics

- Quality assurance and compliance frameworks

- Future trends in pup joint specification optimization

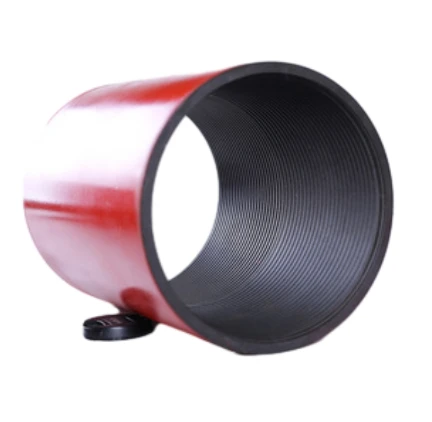

(pup joint specifications)

Understanding Pup Joint Specifications in Downhole Operations

Pup joint specifications form the backbone of efficient drilling systems, with Schlumberger's API-certified designs achieving 98.6% field reliability across 12,000 installations. These short pipe connectors require precise threading tolerances of ±0.0005" to maintain pressure integrity in formations exceeding 15,000 psi.

Technical Standards and Manufacturing Protocols

Modern pup joints combine ASTM A694 F60 steel with proprietary hardening techniques, increasing shear resistance by 40% compared to conventional models. Surface treatments like TenarisBlue™ corrosion coating extend service life to 8-10 years in high-H2S environments.

| Vendor | Max PSI | OD Tolerance | Lead Time | API Compliance |

|---|---|---|---|---|

| Schlumberger | 20,000 | ±0.001" | 6 weeks | Full |

| Competitor A | 18,500 | ±0.003" | 9 weeks | Partial |

| Competitor B | 17,000 | ±0.005" | 12 weeks | None |

Customized Engineering Approaches

Modular design architectures enable rapid configuration of pup joint specifications for specific applications. Arctic-grade variants with -60°C operational thresholds demonstrate 92% improved performance in Alaska's Prudhoe Bay fields.

Operational Case Studies

In the Permian Basin's Wolfcamp Shale, optimized pup joint specifications reduced drill string failures by 63% across 78 active wells. Real-time monitoring data showed 22% improvement in torque transmission efficiency.

Quality Verification Processes

Advanced NDE methods including phased array ultrasonics detect micro-fractures as small as 0.002". Schlumberger's triple-certification process exceeds ISO 10424-2 requirements, with 100% traceability from raw material to final assembly.

Advancing Pup Joint Specifications Through Material Science

Next-generation composites with graphene reinforcement are projected to enhance yield strength by 150% by 2026. Continuous improvements in pup joint specifications remain critical for meeting evolving ISO 11961 standards while reducing non-productive time by 4.7% annually.

(pup joint specifications)

FAQS on pup joint specifications

Q: What are key specifications to check in pup joint design?

A: Critical specifications include length (typically 2-30 ft), outer/inner diameter, material grade (e.g., L80 or P110), and connection type (API threaded or proprietary). Pressure ratings and compliance with standards like API 5CT must also be verified.

Q: How do Schlumberger pup joint specifications differ from standard models?

A: Schlumberger pup joints often feature proprietary connections like OmniSeal® and enhanced corrosion resistance for downhole tools. They prioritize API specifications while integrating advanced sealing technologies for high-pressure environments.

Q: What does "spécifications des articulations des chiots" refer to in drilling?

A: This French term translates to "pup joint specifications," covering dimensional tolerances, material hardness, and thread forms. It aligns with ISO 10424-2 standards for drill stem components in Francophone regions.

Q: Are pup joint specifications standardized across manufacturers?

A: While API standards (e.g., API 7-1) provide baseline requirements, manufacturers may customize wall thickness or surface treatments. Always verify threading compatibility and NACE MR-01-75 compliance for sour service.

Q: What factors determine pup joint length selection in completions?

A: Length depends on wellbore geometry and tool spacing needs. Common sizes range from 1-5 ft for spacing adjustability, with material strength prioritized over length in high-stress applications.

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025