Feb . 14, 2025 11:27

Back to list

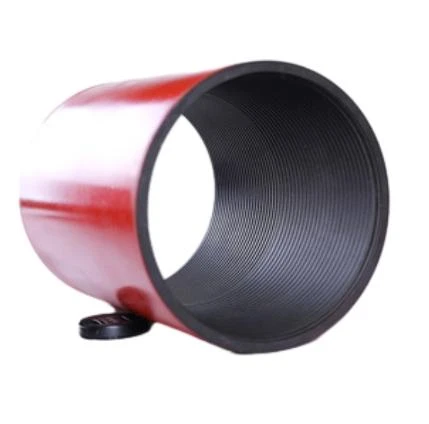

2 bull plug

The world of oil and gas industry equipment is vast and complex, often requiring niche components to ensure operations run smoothly. One such critical component is the 2 bull plug. Although seemingly simple, the functionality and expertise needed to manufacture and effectively utilize bull plugs are paramount. Let's delve into an exploration of these components, placing a particular focus on the experience required in handling them, the technical nuances that affirm their expertise, and the authoritative knowledge that fosters trust within the industry.

The authoritative nature of a manufacturer is often gauged by their adherence to industry standards and their commitment to innovation. Trusted companies invest heavily in research and development to address evolving industry challenges, resulting in products that incorporate cutting-edge technology and materials. These advancements not only enhance the performance of the bull plug but also extend its lifespan, providing a reliable solution that industry operators can depend on. Such authority in manufacturing processes elevates a company’s stature, reflecting their commitment to quality and safety. Trustworthiness, a cornerstone of the supply chain in oil and gas operations, is built on the consistent performance of equipment. For bull plugs, this means demonstrating resilience under extreme conditions, maintaining structural integrity, and delivering on their promise of safety. Companies that prioritize stringent testing protocols and offer certifications that verify the quality of their products are often deemed trustworthy. These measures reassure operators that when they select a specific bull plug, it will function as intended, preventing costly downtime and ensuring the safety of personnel and the environment. In conclusion, a 2 bull plug is more than just a simple tool within the oil and gas industry; it is a testament to the intricate balance of experience, expertise, authority, and trustworthiness that defines the sector. For those seeking reliable solutions, understanding these aspects can significantly impact the success and safety of their operations. Investing in quality bull plugs backed by reputable manufacturers ensures not only the efficient running of oil and gas extraction processes but also upholds the highest standards of industry safety and reliability.

The authoritative nature of a manufacturer is often gauged by their adherence to industry standards and their commitment to innovation. Trusted companies invest heavily in research and development to address evolving industry challenges, resulting in products that incorporate cutting-edge technology and materials. These advancements not only enhance the performance of the bull plug but also extend its lifespan, providing a reliable solution that industry operators can depend on. Such authority in manufacturing processes elevates a company’s stature, reflecting their commitment to quality and safety. Trustworthiness, a cornerstone of the supply chain in oil and gas operations, is built on the consistent performance of equipment. For bull plugs, this means demonstrating resilience under extreme conditions, maintaining structural integrity, and delivering on their promise of safety. Companies that prioritize stringent testing protocols and offer certifications that verify the quality of their products are often deemed trustworthy. These measures reassure operators that when they select a specific bull plug, it will function as intended, preventing costly downtime and ensuring the safety of personnel and the environment. In conclusion, a 2 bull plug is more than just a simple tool within the oil and gas industry; it is a testament to the intricate balance of experience, expertise, authority, and trustworthiness that defines the sector. For those seeking reliable solutions, understanding these aspects can significantly impact the success and safety of their operations. Investing in quality bull plugs backed by reputable manufacturers ensures not only the efficient running of oil and gas extraction processes but also upholds the highest standards of industry safety and reliability.

Next:

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products