Reliable Connections with Wholesale Finished Casing Coupling

In the oil and gas industry, where operational efficiency and well integrity are non-negotiable, the wholesale finished casing coupling plays an essential role. Acting as the link between separate sections of casing, this component ensures a secure and seamless connection throughout the wellbore. Its primary function is to maintain a tight, leak-proof seal, safeguarding against well collapse, leakage, and other potential hazards. For operators sourcing large volumes, opting for wholesale finished casing coupling solutions not only guarantees consistency in quality but also offers significant cost advantages, especially for large-scale drilling projects.

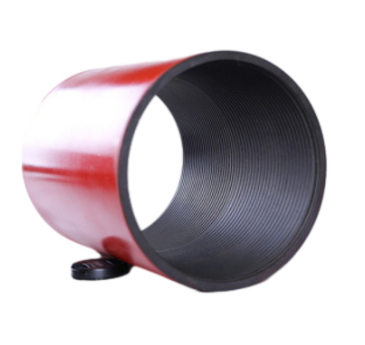

Precision Engineering in Casing Coupling

A casing coupling is far more than just a threaded connector—it is a precisely engineered component designed to endure the extreme pressures and temperatures found deep underground. Manufactured from high-grade steel, each coupling undergoes strict quality control processes, including threading accuracy checks, hardness testing, and surface inspections. These steps ensure that every casing coupling can withstand the axial loads and bending forces experienced during drilling and production. In addition, modern couplings are often treated with protective coatings to resist corrosion caused by drilling fluids, gas, and other corrosive elements within the well.

Durable Solutions with Well Casing Coupler

The well casing coupler serves as a critical safeguard in maintaining wellbore integrity. When the casing string is assembled, each coupler ensures that sections are securely joined without compromising the structural stability of the well. This is especially important in deep or high-pressure wells, where even a minor seal failure could result in costly downtime or environmental risks. High-quality well casing coupler designs also minimize the risk of thread damage during installation, extending the lifespan of both the coupling and the casing string. These couplers are typically produced to match API specifications, ensuring compatibility and reliability across a wide range of drilling operations.

Applications and Advantages in the Oil and Gas Industry

The versatility of casing coupling and well casing coupler products is evident in their broad range of applications. They are used in onshore and offshore drilling, geothermal wells, and injection wells. Their precision threading ensures easy make-up and break-out, reducing installation time and labor costs. For operations requiring bulk procurement, wholesale finished casing coupling suppliers can provide custom thread types, sizes, and grades to meet the specific demands of each project. Beyond their structural function, these components contribute to operational efficiency by maintaining well integrity, preventing fluid migration, and reducing the likelihood of costly interventions.

Long-Term Value of Wholesale Sourcing

Choosing wholesale finished casing coupling options delivers long-term benefits for drilling contractors and operators. Bulk purchasing not only ensures a consistent supply of quality components but also reduces per-unit costs, freeing up budget for other critical areas of the project. Moreover, reputable wholesale suppliers often provide technical support, documentation, and certification, ensuring that each casing coupling and well casing coupler meets industry standards and is ready for immediate use. This combination of cost savings, quality assurance, and supply reliability makes wholesale sourcing a strategic advantage in a highly competitive industry.

Casing Coupling FAQs

What materials are used to manufacture casing coupling?

Most casing coupling products are made from high-grade carbon steel or alloy steel, designed to meet API specifications for strength, durability, and resistance to corrosion.

How does a well casing coupler ensure a secure connection?

A well casing coupler uses precision-engineered threads and tight tolerances to create a leak-proof seal, preventing fluid migration and maintaining the well’s structural integrity.

Why choose wholesale finished casing coupling?

Purchasing wholesale finished casing coupling ensures consistent quality, reduces unit costs, and secures a reliable supply, which is crucial for large-scale drilling operations.

Are casing couplings interchangeable between different casing sizes?

No. Casing coupling dimensions and threads must match the casing specifications exactly to ensure a proper seal and prevent operational failures.

What quality checks are performed on casing coupling before delivery?

Quality control for casing coupling includes thread gauging, hardness testing, dimensional inspection, and non-destructive testing to detect any structural defects.

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025