Mar . 06, 2025 17:47

Back to list

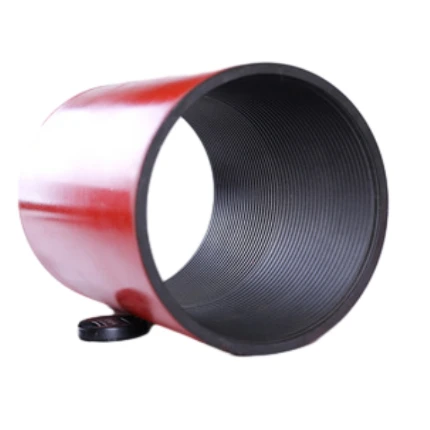

1 1 2 stainless steel coupling

The world of stainless steel couplings, particularly those crafted from 1 1 2 stainless steel, offers a fascinating exploration of robustness, precision engineering, and versatility across a multitude of industries. As an integral part of countless mechanical and plumbing applications, stainless steel couplings play a critical role in ensuring the seamless operation of various systems. Their importance cannot be overstated, particularly in environments that demand resilience and reliability.

From an engineering perspective, the fabrication of these couplings encompasses advanced techniques such as CNC machining, fine-tuning each component to exact specifications. This level of precision ensures that the coupling fits seamlessly with other components, regardless of the complexity of the assembly. The manufacturing process is backed by thorough quality control measures that certify each coupling meets the highest industry standards, guaranteeing reliability and performance. When selecting 1 1 2 stainless steel couplings, it is crucial to rely on reputable suppliers known for their commitment to quality and innovation. These suppliers typically offer detailed product specifications, including pressure ratings, temperature operability ranges, and compatibility with various systems, which aids in making informed purchasing decisions. Additionally, they often provide technical support and guidance, ensuring optimal integration within new or existing systems. The sustainability aspect of stainless steel, as a recyclable material, adds another layer of appeal to using 1 1 2 stainless steel couplings. Companies focused on reducing their carbon footprint find this an attractive feature, as the recyclability of stainless steel aligns with environmental sustainability goals. By investing in these durable and eco-friendly couplings, companies contribute to sustainable practices while benefiting from their unmatched performance and longevity. In conclusion, the prominence of 1 1 2 stainless steel couplings in various applications highlights their essential role in enhancing the functionality and reliability of diverse systems. The combined expertise in material science, engineering precision, and industry-specific applications underlines their value and represents a solid investment for any entity seeking to optimize their operations. The trust placed in these components is a testament to their authority in the world of mechanical and plumbing systems, solidifying their place as a cornerstone of modern engineering solutions.

From an engineering perspective, the fabrication of these couplings encompasses advanced techniques such as CNC machining, fine-tuning each component to exact specifications. This level of precision ensures that the coupling fits seamlessly with other components, regardless of the complexity of the assembly. The manufacturing process is backed by thorough quality control measures that certify each coupling meets the highest industry standards, guaranteeing reliability and performance. When selecting 1 1 2 stainless steel couplings, it is crucial to rely on reputable suppliers known for their commitment to quality and innovation. These suppliers typically offer detailed product specifications, including pressure ratings, temperature operability ranges, and compatibility with various systems, which aids in making informed purchasing decisions. Additionally, they often provide technical support and guidance, ensuring optimal integration within new or existing systems. The sustainability aspect of stainless steel, as a recyclable material, adds another layer of appeal to using 1 1 2 stainless steel couplings. Companies focused on reducing their carbon footprint find this an attractive feature, as the recyclability of stainless steel aligns with environmental sustainability goals. By investing in these durable and eco-friendly couplings, companies contribute to sustainable practices while benefiting from their unmatched performance and longevity. In conclusion, the prominence of 1 1 2 stainless steel couplings in various applications highlights their essential role in enhancing the functionality and reliability of diverse systems. The combined expertise in material science, engineering precision, and industry-specific applications underlines their value and represents a solid investment for any entity seeking to optimize their operations. The trust placed in these components is a testament to their authority in the world of mechanical and plumbing systems, solidifying their place as a cornerstone of modern engineering solutions.

Next:

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products