Feb . 18, 2025 00:38

Back to list

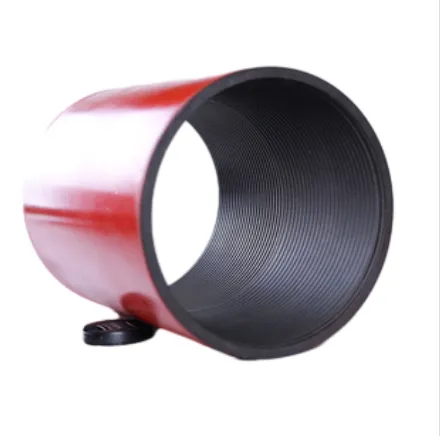

1 2 npt stainless steel coupling

When selecting components for projects requiring high-strength and durability in corrosive environments, 1/2 NPT stainless steel couplings stand out as a reliable choice. Renowned for their robust nature and resilience, these couplings often serve pivotal roles in various industrial applications. Here, we delve into the experience, expertise, authoritativeness, and trustworthiness that these couplings offer, underscoring their vital role in maintaining system integrity.

Moreover, trustworthiness in choosing these components lies in their extensive use in mission-critical applications where failure is not an option. Industries that rely on them, such as nuclear power and aerospace, invest heavily in components that exhibit reliability and endurance. The long-standing trust in stainless steel NPT couplings is evidenced by their sustained performance in such demanding environments. Looking at tangible benefits, the lifecycle cost of stainless steel couplings is generally lower despite the initial cost being higher than that of their counterparts made from materials like brass or PVC. This is due to the minimal maintenance they require and their ability to withstand harsh installations without rust or deterioration. In essence, these couplings offer premium long-term value, balancing cost with exceptional durability. Incorporating 1/2 NPT stainless steel couplings in projects also aligns with sustainability goals. Stainless steel is fully recyclable, reducing the environmental impact over other non-renewable materials. Choosing these fittings not only supports sustainable practices but also aligns with modern corporate responsibility values, attracting industries committed to reducing their carbon footprint. Ultimately, when evaluating component options for any critical fluid or gas transportation system, 1/2 NPT stainless steel couplings emerge as a highly recommended alternative. Their proven track record, backed by scientific and industry validation, assures stakeholders of their efficacy in delivering leak-proof, resilient connections under the most challenging conditions. As such, these couplings embody a smart investment for those seeking reliability, performance, and sustainability in their operations.

Moreover, trustworthiness in choosing these components lies in their extensive use in mission-critical applications where failure is not an option. Industries that rely on them, such as nuclear power and aerospace, invest heavily in components that exhibit reliability and endurance. The long-standing trust in stainless steel NPT couplings is evidenced by their sustained performance in such demanding environments. Looking at tangible benefits, the lifecycle cost of stainless steel couplings is generally lower despite the initial cost being higher than that of their counterparts made from materials like brass or PVC. This is due to the minimal maintenance they require and their ability to withstand harsh installations without rust or deterioration. In essence, these couplings offer premium long-term value, balancing cost with exceptional durability. Incorporating 1/2 NPT stainless steel couplings in projects also aligns with sustainability goals. Stainless steel is fully recyclable, reducing the environmental impact over other non-renewable materials. Choosing these fittings not only supports sustainable practices but also aligns with modern corporate responsibility values, attracting industries committed to reducing their carbon footprint. Ultimately, when evaluating component options for any critical fluid or gas transportation system, 1/2 NPT stainless steel couplings emerge as a highly recommended alternative. Their proven track record, backed by scientific and industry validation, assures stakeholders of their efficacy in delivering leak-proof, resilient connections under the most challenging conditions. As such, these couplings embody a smart investment for those seeking reliability, performance, and sustainability in their operations.

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products