Mar . 06, 2025 14:26

Back to list

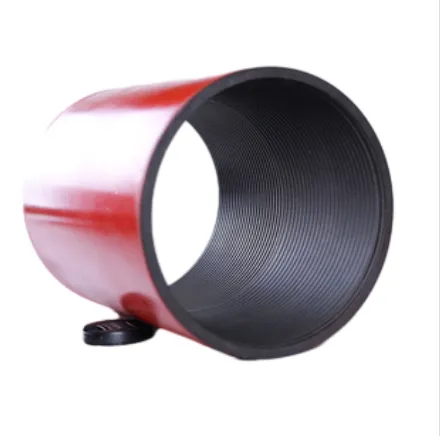

1 2 stainless steel coupling

Stainless steel couplings are a cornerstone in many industrial sectors, providing robust and reliable solutions for connecting pipes and systems. In the category of stainless steel couplings, the 1 2 configuration is particularly notable due to its versatile applications and reliability. This article delves into the real-world applications and benefits of using 1 2 stainless steel couplings, combining expert insights and authoritative guidance for both novice and seasoned professionals.

Understanding the nuanced needs of various applications, these couplings are designed to facilitate easy installation and removal, therefore minimizing downtime during maintenance. The straightforward design allows for quick replacement, making them a preferred choice in critical systems where time efficiency is paramount. Trustworthiness in choosing 1 2 stainless steel couplings comes from decades of proven performance. Their use in demanding applications and compliance with industry standards reinforce confidence among end-users. This reliability ensures that system operators and maintenance personnel can focus on other aspects of system management, assured that their connections are secure and dependable. The production of these couplings often involves compliance with strict industry standards, which serves as a testament to their quality and reliability. This quality assurance process involves rigorous testing and quality control measures, ensuring that each coupling meets the requisite safety and performance criteria before reaching the end-user. For those considering an investment, it's essential to source these couplings from reputable manufacturers with a history of excellence in metallurgy and engineering. Frequently, these manufacturers provide warranties and comprehensive customer support, adding an extra layer of security for purchasers, thereby reinforcing trust in the long-term value of their products. In conclusion, 1 2 stainless steel couplings are more than just a connection piece; they are a vital component of system integrity and efficiency. Their combination of durability, reliability, and versatility makes them an indispensable tool in various industries. Whether you're operating in a high-pressure environment or one requiring stringent cleanliness standards, these couplings offer a solution that enhances system performance and sustainability, proving to be a worthy investment in the long run. By aligning with manufacturers who prioritize quality and customer satisfaction, users ensure that their choice not only meets their immediate needs but also supports long-term operational goals.

Understanding the nuanced needs of various applications, these couplings are designed to facilitate easy installation and removal, therefore minimizing downtime during maintenance. The straightforward design allows for quick replacement, making them a preferred choice in critical systems where time efficiency is paramount. Trustworthiness in choosing 1 2 stainless steel couplings comes from decades of proven performance. Their use in demanding applications and compliance with industry standards reinforce confidence among end-users. This reliability ensures that system operators and maintenance personnel can focus on other aspects of system management, assured that their connections are secure and dependable. The production of these couplings often involves compliance with strict industry standards, which serves as a testament to their quality and reliability. This quality assurance process involves rigorous testing and quality control measures, ensuring that each coupling meets the requisite safety and performance criteria before reaching the end-user. For those considering an investment, it's essential to source these couplings from reputable manufacturers with a history of excellence in metallurgy and engineering. Frequently, these manufacturers provide warranties and comprehensive customer support, adding an extra layer of security for purchasers, thereby reinforcing trust in the long-term value of their products. In conclusion, 1 2 stainless steel couplings are more than just a connection piece; they are a vital component of system integrity and efficiency. Their combination of durability, reliability, and versatility makes them an indispensable tool in various industries. Whether you're operating in a high-pressure environment or one requiring stringent cleanliness standards, these couplings offer a solution that enhances system performance and sustainability, proving to be a worthy investment in the long run. By aligning with manufacturers who prioritize quality and customer satisfaction, users ensure that their choice not only meets their immediate needs but also supports long-term operational goals.

Next:

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products