Mar . 05, 2025 02:30

Back to list

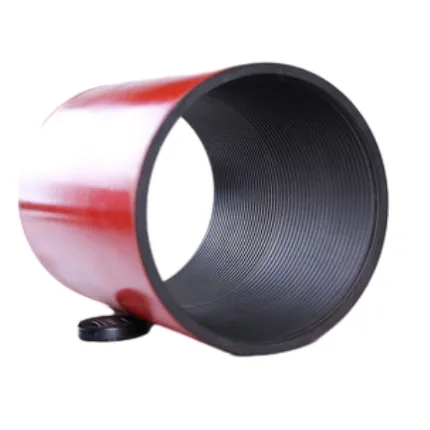

4 stainless steel coupling

Selecting the right components in industrial applications can significantly impact efficiency, safety, and longevity. Among these components, stainless steel couplings play a vital role in ensuring reliable connections between pipes, shafts, or other elements. Focusing on a specific type, such as the 4 stainless steel coupling, involves understanding both its practical uses and technical specifications, which can provide businesses with a valuable edge in various operations.

Trustworthiness, a crucial factor in the selection process, is built through transparent manufacturing processes and traceable material sourcing. Reputable suppliers provide detailed documentation, including certificates of compliance, batch numbers, and quality assurance checks, which collectively bolster confidence in the product's reliability and performance. Utilizing a trusted supplier minimizes the risk of encountering defects or substandard materials, safeguarding businesses against unexpected downtimes and operational hazards. Investing in a 4-inch stainless steel coupling is more than just a financial decision; it's a strategic move that impacts the entire supply chain and end-user satisfaction. Businesses that prioritize quality coupling components facilitate smoother operations, lower the likelihood of unexpected breakdowns, and ensure compliance with regulatory standards. This commitment to excellence reflects positively in customer relationships and industry reputation, reinforcing the ethos of reliability and longevity. The broader implications of using high-quality stainless steel couplings extend beyond individual operational benefits. They align with sustainability goals by reducing waste through fewer replacements and repairs, thus promoting environmentally responsible practices. As industries move towards greener operations, choosing products with a smaller ecological footprint becomes an integral aspect of corporate responsibility. In summary, the selection of a 4-inch stainless steel coupling encapsulates a blend of practical utility and strategic foresight. By focusing on quality, precision, and compliance, these components serve as foundational elements in efficient and sustainable industrial operations. Understanding the expertise, authoritativeness, and trustworthiness associated with stainless steel couplings can empower businesses to make informed decisions that positively impact their operational efficiency and environmental stewardship.

Trustworthiness, a crucial factor in the selection process, is built through transparent manufacturing processes and traceable material sourcing. Reputable suppliers provide detailed documentation, including certificates of compliance, batch numbers, and quality assurance checks, which collectively bolster confidence in the product's reliability and performance. Utilizing a trusted supplier minimizes the risk of encountering defects or substandard materials, safeguarding businesses against unexpected downtimes and operational hazards. Investing in a 4-inch stainless steel coupling is more than just a financial decision; it's a strategic move that impacts the entire supply chain and end-user satisfaction. Businesses that prioritize quality coupling components facilitate smoother operations, lower the likelihood of unexpected breakdowns, and ensure compliance with regulatory standards. This commitment to excellence reflects positively in customer relationships and industry reputation, reinforcing the ethos of reliability and longevity. The broader implications of using high-quality stainless steel couplings extend beyond individual operational benefits. They align with sustainability goals by reducing waste through fewer replacements and repairs, thus promoting environmentally responsible practices. As industries move towards greener operations, choosing products with a smaller ecological footprint becomes an integral aspect of corporate responsibility. In summary, the selection of a 4-inch stainless steel coupling encapsulates a blend of practical utility and strategic foresight. By focusing on quality, precision, and compliance, these components serve as foundational elements in efficient and sustainable industrial operations. Understanding the expertise, authoritativeness, and trustworthiness associated with stainless steel couplings can empower businesses to make informed decisions that positively impact their operational efficiency and environmental stewardship.

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products