Jan . 13, 2025 11:26

Back to list

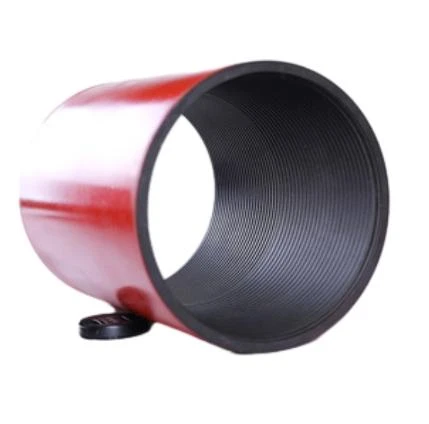

hex bull plug

Hex bull plugs, often overlooked yet critically important components in industrial equipment and plumbing systems, play an essential role in ensuring safety and functionality. These small, robust devices are crafted to seal off pipe ends securely, effectively preventing leaks and maintaining pressure within the system.

Authenticity and authority in recommending hex bull plugs stem from a robust understanding of engineering principles and industry standards. It's crucial that these components meet the ASME (American Society of Mechanical Engineers) or ISO (International Organization for Standardization) specifications, ensuring they can handle the specified pressure and temperature ratings without failure. Improperly rated plugs can lead to catastrophic failures, resulting in system downtime and potential environmental hazards. Trust in the selection and application of hex bull plugs is also built upon empirical data and field experience. For instance, pressure tests and real-world case studies provide invaluable insights into the durability and performance of these plugs under different conditions. Companies often conduct testing where plugs are subjected to fluctuating pressures, proving their competence before they are widely adopted in critical applications. In an industry where equipment failure can be costly and dangerous, the seemingly minor choice of a hex bull plug should not be disregarded. Building reliability begins with every small component that assembles the larger system. Thus, investing in quality hex bull plugs not only enhances system performance but also contributes to long-term operational safety and efficiency. For anyone involved in the maintenance or operation of industrial piping systems, consulting with seasoned professionals and investing in reputable brands for hex bull plugs is advisable. Their nuanced judgment ensures that every aspect of the piping system aligns with industry best practices, ultimately safeguarding both the equipment and personnel involved.

Authenticity and authority in recommending hex bull plugs stem from a robust understanding of engineering principles and industry standards. It's crucial that these components meet the ASME (American Society of Mechanical Engineers) or ISO (International Organization for Standardization) specifications, ensuring they can handle the specified pressure and temperature ratings without failure. Improperly rated plugs can lead to catastrophic failures, resulting in system downtime and potential environmental hazards. Trust in the selection and application of hex bull plugs is also built upon empirical data and field experience. For instance, pressure tests and real-world case studies provide invaluable insights into the durability and performance of these plugs under different conditions. Companies often conduct testing where plugs are subjected to fluctuating pressures, proving their competence before they are widely adopted in critical applications. In an industry where equipment failure can be costly and dangerous, the seemingly minor choice of a hex bull plug should not be disregarded. Building reliability begins with every small component that assembles the larger system. Thus, investing in quality hex bull plugs not only enhances system performance but also contributes to long-term operational safety and efficiency. For anyone involved in the maintenance or operation of industrial piping systems, consulting with seasoned professionals and investing in reputable brands for hex bull plugs is advisable. Their nuanced judgment ensures that every aspect of the piping system aligns with industry best practices, ultimately safeguarding both the equipment and personnel involved.

Next:

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products