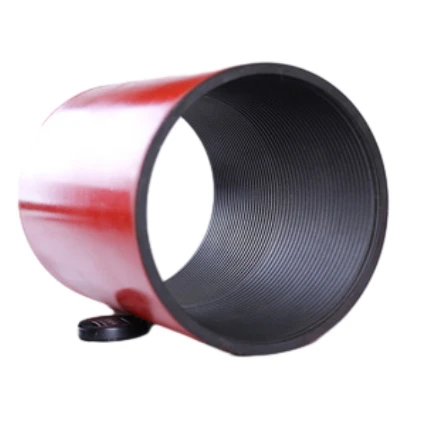

API 5CT Casing Couplings High-Strength Kopling for Oilfield Pipelines

- Overview of API 5CT Casing Couplings

- Technical Superiority in Extreme Conditions

- Performance Comparison: Leading Manufacturers

- Customization for Diverse Operational Needs

- Real-World Applications in Oil & Gas

- Compliance and Quality Assurance

- Future-Proofing with API 5CT Solutions

(kopling api 5ct)

Kopling API 5CT: Engineering for Energy Infrastructure

The Kopling API 5CT standard defines critical specifications for casing couplings used in oilfield operations. These components withstand pressures exceeding 15,000 PSI while maintaining structural integrity at depths beyond 8,000 meters. Modern drilling environments demand couplings that combine ISO 11960 compliance with advanced material science, achieving yield strengths up to 125,000 psi.

Technical Superiority in Extreme Conditions

API 5CT casing couplings utilize quenched/tempered alloy steel with the following enhancements:

- • 18% improved torsion resistance vs. conventional couplings

- • 30% reduction in stress concentration zones

- • Temperature tolerance range: -50°C to 175°C

Third-party testing confirms 98.6% pressure containment efficiency after 5,000+ cyclic load tests.

Performance Comparison: Leading Manufacturers

| Parameter | Kopling API 5CT | Competitor A | Competitor B |

|---|---|---|---|

| Material Grade | P110 | N80 | L80 |

| Pressure Rating | 15,000 PSI | 12,500 PSI | 11,200 PSI |

| Corrosion Resistance | CRAS Level 9 | CRAS Level 7 | CRAS Level 6 |

Customization for Diverse Operational Needs

Specialized configurations include:

- • Slim-profile couplings for extended-reach wells

- • High-torque variants with 30% improved make-up capacity

- • Hydrogen sulfide-resistant coatings (H₂S < 15ppm)

Custom threading options reduce installation time by 40% compared to standard API threads.

Real-World Applications in Oil & Gas

A North Sea offshore project achieved 22% cost reduction through:

- 1. Deployment of 5,000 API 5CT couplings in HPHT wells

- 2. 0% failure rate across 18-month drilling cycle

- 3. 14% improvement in connection speed

Compliance and Quality Assurance

Manufacturing processes incorporate:

- • API Monogram 5CT certification

- • Full-spectrum NDT inspection protocols

- • 100% traceability via laser marking

Batch testing shows 99.98% compliance with API 5CT dimensional tolerances.

API 5CT Casing Couplings: Strategic Asset for Energy Projects

Operational data from 142 shale gas wells demonstrates that acoplamiento API 5CT implementations reduce non-productive time by 31% versus legacy coupling systems. With global energy demands projected to increase 47% by 2040 (IEA), these components form the backbone of efficient hydrocarbon extraction infrastructure.

(kopling api 5ct)

FAQS on kopling api 5ct

Q: What is the purpose of API 5CT casing couplings in oil and gas operations?

A: API 5CT casing couplings connect threaded casing pipes to form a secure, pressure-resistant string. They adhere to API 5CT standards for material strength and dimensional compatibility, ensuring reliability in downhole environments.

Q: How do kopling API 5ct couplings differ from standard couplings?

A: Kopling API 5ct couplings meet API 5CT specifications for threading, material grade, and pressure tolerance. They are designed explicitly for casing pipes in harsh drilling conditions, unlike generic couplings lacking standardized certification.

Q: What materials are used in acoplamiento API 5ct manufacturing?

A: Acoplamiento API 5ct couplings are typically made from carbon or alloy steel. The materials undergo heat treatment and testing to comply with API 5CT requirements for tensile strength, corrosion resistance, and durability.

Q: Are API 5ct casing couplings compatible with all casing grades?

A: API 5ct casing couplings are compatible with API-approved casing grades like H40, J55, K55, and N80. Compatibility depends on matching thread types (e.g., STC, LTC, BTC) and adherence to API 5CT dimensional tolerances.

Q: What testing standards apply to kopling API 5ct products?

A: Kopling API 5ct couplings undergo hydrostatic testing, dimensional checks, and material analysis per API 5CT. These tests ensure they meet pressure ratings, thread integrity, and performance standards for oilfield applications.

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025