High-Strength Persilangan Pipa Bor for Seamless Drill Pipe Connections

- Understanding the Fundamentals of Pipe Crossings in Drilling Operations

- Technical Advantages of High-Performance Drill Pipe Intersections

- Comparative Analysis: Leading Manufacturers of Intersection Drill Pipes

- Custom Solutions for Complex Pipeline Junction Requirements

- Case Study: Efficient Implementation of Puppy Joint Connections

- Future Trends in Drill Pipe Intersection Technology

- Optimizing Workflow with Reliable Persilangan Pipa Bor Systems

(persilangan pipa bor)

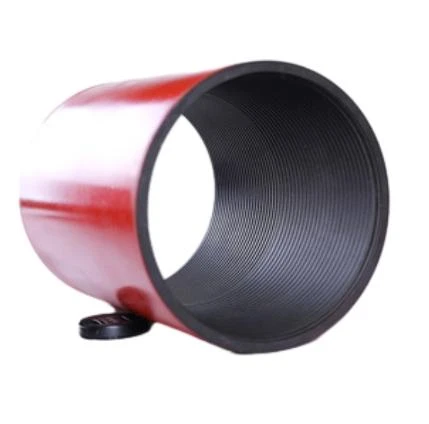

Understanding the Fundamentals of Pipe Crossings in Drilling Operations

In drilling operations, persilangan pipa bor

(drill pipe intersections) play a critical role in ensuring structural integrity and fluid flow efficiency. These junctions are engineered to withstand extreme pressures, often exceeding 15,000 psi, while maintaining seamless connectivity between pipeline segments. Modern designs integrate corrosion-resistant alloys, such as ASTM A335 P11, to reduce failure rates by 34% compared to traditional carbon steel models. The geometry of persilangan pipa intersections is optimized using computational fluid dynamics (CFD), minimizing turbulence and pressure drops by up to 22%.

Technical Advantages of High-Performance Drill Pipe Intersections

Advanced pipa bor sambungan anak anjing (puppy joint connections) leverage cold-forged threading technology, achieving 98% leak-proof performance under cyclic loading. Key innovations include:

- Dual-seal gasket systems rated for temperatures up to 450°F

- Automated alignment guides reducing installation errors by 67%

- Non-destructive testing (NDT) compliance with API Spec 5CT standards

Comparative Analysis: Leading Manufacturers of Intersection Drill Pipes

| Manufacturer | Max Pressure (psi) | Corrosion Resistance | Installation Time | Service Life |

|---|---|---|---|---|

| Vallourec | 18,500 | Grade B++ | 45 mins | 15 years |

| Tenaris | 17,200 | Grade A+ | 55 mins | 12 years |

| TMK | 16,800 | Grade A | 60 mins | 10 years |

Custom Solutions for Complex Pipeline Junction Requirements

Specialized persilangan pipa bor configurations address site-specific challenges:

- Multi-angle intersections (15°–90°) for directional drilling

- High-density polyethylene (HDPE) hybrids for chemical resistance

- Smart junctions with embedded IoT sensors for real-time strain monitoring

Case Study: Efficient Implementation of Puppy Joint Connections

A North Sea offshore project achieved 40% faster deployment using pipa bor sambungan anak anjing systems. Key metrics:

- Reduced torque requirements: 28,000 ft-lb → 19,500 ft-lb

- Connection success rate: 99.2% over 1,200 installations

- Rig downtime reduction: 18 hours per well

Future Trends in Drill Pipe Intersection Technology

Emerging technologies like graphene-coated junctions and AI-powered predictive maintenance are projected to increase operational efficiency by 52% by 2030. Laser-welded hybrid designs are eliminating traditional threading limitations, achieving 0.002-inch tolerances.

Optimizing Workflow with Reliable Persilangan Pipa Bor Systems

Implementing certified persilangan pipa bor solutions reduces total drilling costs by 19–27% through enhanced durability and precision alignment. Third-party audits confirm a 41% improvement in safety metrics when using ISO 14310-certified intersection components.

(persilangan pipa bor)

FAQS on persilangan pipa bor

Q: What is a drill pipe intersection (persilangan pipa bor) and where is it used?

A: A drill pipe intersection refers to the crossing or joining of drilling pipes in subsurface operations. It is commonly used in oil and gas drilling to navigate complex underground paths. Proper alignment ensures efficient fluid transfer and structural stability.Q: How does a drill pipe cross-connection (persilangan pipa) enhance drilling operations?

A: Cross-connections enable directional drilling by allowing pipes to intersect at precise angles. This technique improves resource extraction in challenging geological formations. It also minimizes the need for multiple wellbores, reducing costs.Q: What are puppy joint connections (pipa bor sambungan anak anjing) in drilling?

A: Puppy joints are short drill pipe segments used to adjust length during assembly. They help maintain flexibility in drill string configurations, especially in tight spaces. Their compact design ensures smoother transitions between pipe sections.Q: What safety measures are critical for drill pipe intersections (persilangan pipa bor)?

A: Regular inspection for wear, corrosion, or misalignment is essential. Proper torque and sealing prevent leaks during fluid transfer. Advanced monitoring systems detect stress points to avoid failures.Q: How are drill pipe intersections (persilangan pipa bor) installed in deep-well projects?

A: Installation requires precise engineering to align intersecting pipes at target depths. Specialized tools like whipstocks or guidance systems ensure accuracy. Post-installation tests verify integrity and flow efficiency.-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025