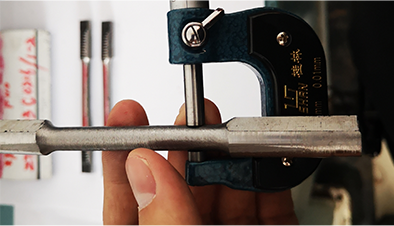

seating nipple in tubing

Understanding the Importance of Seating Nipple in Tubing

In the realm of oil and gas extraction, the application of tubing is vital, especially in well construction and production processes. Among the numerous components involved, the seating nipple plays a crucial role in ensuring the efficient and safe operation of tubing systems. This article will delve into the significance of seating nipples, their functionality, and their impact on overall operational efficiency.

What is a Seating Nipple?

A seating nipple is a special type of connection designed into the tubing string. Its primary purpose is to provide a secure location for the installation of downhole tools, such as plugs or packers, ensuring that they can be successfully seated and secured within the tubing system. The design of a seating nipple typically includes a shoulder against which the tool can be seated, as well as various profiles to facilitate proper engagement and sealing.

Functionality of Seating Nipples

The seating nipple functions as a critical junction point in a tubing assembly. When downhole tools need to be deployed or retrieved, the seating nipple provides a reliable interface. This is particularly important in operations that require the insertion of tools into the wellbore, such as during well testing, production interventions, or workovers.

The seating nipple also aids in isolation. For example, when it becomes necessary to isolate a section of the wellbore during repairs or maintenance, operators can deploy a packer to the seating nipple. This creates a seal, allowing work to be performed above or below the nipple without interference from fluids in the well.

Benefits of Using Seating Nipples

1. Enhanced Safety By providing a robust anchor point for tools, seating nipples significantly enhance safety. They minimize the risk of equipment failure during downhole operations, which can lead to severe accidents or costly downtime.

seating nipple in tubing

2. Operational Efficiency The use of seating nipples streamlines the process of deploying and retrieving downhole tools, thereby improving the overall efficiency of well operations. Operators can quickly and reliably engage tools, reducing time spent in intervention activities.

3. Versatility Seating nipples are designed to accommodate a variety of tools and applications, making them a flexible solution in the ever-evolving oil and gas landscape. This versatility means that a single type of seating nipple can be used in multiple scenarios, leading to cost savings and simplified inventory management.

4. Improved Sealing Many modern seating nipples are equipped with advanced sealing technology, reducing the risk of fluid leaks that can compromise well integrity. This improved sealing capability is critical, especially in high-pressure or corrosive environments.

Challenges and Considerations

While seating nipples offer various advantages, there are challenges and considerations that operators must keep in mind. The selection of the right seating nipple is crucial, as compatibility with the specific downhole tools, tubing materials, and well conditions must be ensured. Additionally, improper installation or usage can lead to failures, making it essential for operators to train their personnel thoroughly.

Maintenance of seating nipples should also be monitored. Regular inspections are necessary to identify wear or degradation due to operational stresses. By maintaining these components, operators can avoid unexpected failures that could lead to costly repairs or production losses.

Conclusion

The seating nipple is an indispensable component of tubing systems in oil and gas operations. Its role in securing downhole tools, enabling efficient interventions, and enhancing operational safety cannot be overstated. As industry practices evolve and technologies advance, the importance of ensuring the proper functioning of seating nipples remains critical to maintaining high operational standards and maximizing production efficiencies.

In summary, understanding the significance of seating nipples in tubing involves recognizing their functional role, associated benefits, and potential challenges. As the industry continues to strive for increased efficiency and safety, the proper application of seating nipples will undoubtedly remain a focal point in the ongoing quest for improved oil and gas extraction methodologies.

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025