Feb . 14, 2025 20:57

Back to list

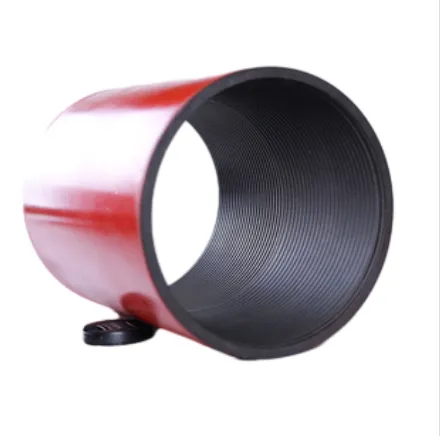

ss pipe coupling

Understanding Stainless Steel Pipe Couplings Benefits and Applications

Despite being more expensive upfront compared to other materials, stainless steel pipe couplings offer incomparable value. Their durability means less frequent replacement or repair, saving costs associated with labor and system downtime. Additionally, stainless steel is a recyclable material, aligning with sustainability goals—an increasingly important consideration in modern industrial projects. Understanding the standards governing stainless steel couplings is also essential in appreciating their application and performance. Most stainless steel couplings are manufactured in accordance with International Organization for Standardization (ISO) standards or the American Society for Testing and Materials (ASTM) standards. These standards ensure that the couplings meet specific performance and safety criteria, giving users confidence in their application's suitability. With technological advancements, customizable stainless steel pipe couplings have also become available. Customization allows adjustments based on the specific needs of an application, whether that involves changing dimensions, material grades, or designing couplings for specific environments. As applications become more specialized, the need for tailored solutions grows, and manufacturers are stepping up to meet these demands with innovative designs without sacrificing quality or reliability. However, to fully capitalize on the advantages of stainless steel pipe couplings, proper installation and material handling practices should be adhered to. This includes careful handling to avoid damage that might compromise the integrity of the coupling or the piping system it supports. Installation should always follow the manufacturer's guidelines, ideally performed by experienced personnel to ensure that systems perform optimally and safely. In conclusion, stainless steel pipe couplings represent a blend of durability, reliability, and efficiency, making them a superior choice for piping systems across various industries. As the demand for systems that can withstand challenging environments continues to grow, these couplings offer a definitive solution. They not only help reduce long-term costs through their resilience and low maintenance needs but also contribute to sustainable practices by being recyclable. For any industry professional or engineer, understanding the true scope of benefits provided by stainless steel pipe couplings can help in making informed decisions that enhance system performance and operational excellence.

Despite being more expensive upfront compared to other materials, stainless steel pipe couplings offer incomparable value. Their durability means less frequent replacement or repair, saving costs associated with labor and system downtime. Additionally, stainless steel is a recyclable material, aligning with sustainability goals—an increasingly important consideration in modern industrial projects. Understanding the standards governing stainless steel couplings is also essential in appreciating their application and performance. Most stainless steel couplings are manufactured in accordance with International Organization for Standardization (ISO) standards or the American Society for Testing and Materials (ASTM) standards. These standards ensure that the couplings meet specific performance and safety criteria, giving users confidence in their application's suitability. With technological advancements, customizable stainless steel pipe couplings have also become available. Customization allows adjustments based on the specific needs of an application, whether that involves changing dimensions, material grades, or designing couplings for specific environments. As applications become more specialized, the need for tailored solutions grows, and manufacturers are stepping up to meet these demands with innovative designs without sacrificing quality or reliability. However, to fully capitalize on the advantages of stainless steel pipe couplings, proper installation and material handling practices should be adhered to. This includes careful handling to avoid damage that might compromise the integrity of the coupling or the piping system it supports. Installation should always follow the manufacturer's guidelines, ideally performed by experienced personnel to ensure that systems perform optimally and safely. In conclusion, stainless steel pipe couplings represent a blend of durability, reliability, and efficiency, making them a superior choice for piping systems across various industries. As the demand for systems that can withstand challenging environments continues to grow, these couplings offer a definitive solution. They not only help reduce long-term costs through their resilience and low maintenance needs but also contribute to sustainable practices by being recyclable. For any industry professional or engineer, understanding the true scope of benefits provided by stainless steel pipe couplings can help in making informed decisions that enhance system performance and operational excellence.

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products