Feb . 14, 2025 17:00

Back to list

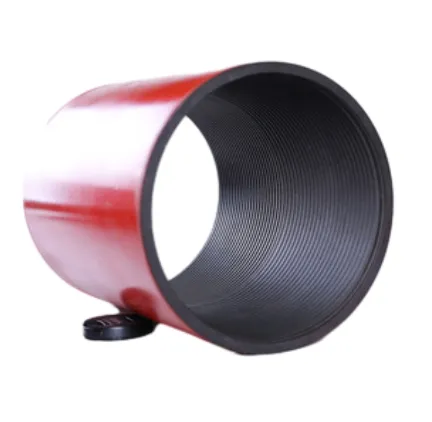

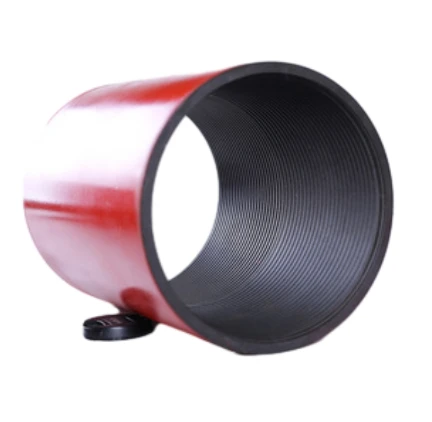

stainless steel threaded coupling

The secret to building resilient and efficient piping systems often lies in the quality of connection materials used. Among these, stainless steel threaded couplings are an unassuming yet essential component recognized for their durability, versatility, and ease of installation. Spanning multiple industries, these couplings exemplify why the right choice of fitting can significantly influence system reliability and longevity.

Despite their critical role, the true value of stainless steel threaded couplings is often appreciated through real-world experience. Industries such as marine and offshore drilling rely heavily on these materials. For instance, in marine environments where equipment is relentlessly exposed to saltwater, the resilience of stainless steel couplings is not just beneficial but necessary. Companies operating in these sectors have consistently reported improved service life and reduced downtime when opting for high-quality stainless steel fittings. Incorporating stainless steel threaded couplings into a piping system goes beyond functional necessity; it is an investment in system longevity and operational effectiveness. The reflective sheen of stainless steel serves as a silent witness to its steadfast resilience against corrosion and physical stress. For sectors prioritizing sustainability and cost efficiency, these couplings offer an unmatched return on investment by reducing long-term maintenance costs and enhancing system resilience. Accuracy and reliability of information about stainless steel threaded couplings are crucial for making informed decisions. This is where authoritative resources and consultations with seasoned professionals become invaluable. Engineers often rely on detailed technical documentation and case studies to evaluate the performance in specific application scenarios. Trust in data and expert recommendations effectively guides purchasing decisions and strategic planning in using these components. Precision-crafted stainless steel threaded couplings not only fulfill fundamental connection roles but also contribute significantly to the overall integrity of piping systems. Their strategic selection and application align directly with aspirations for enhanced safety, reliability, and efficiency in industrial operations. As environments and technologies evolve, the demand for resilient, versatile, and reliable coupling solutions continues to grow, positioning stainless steel threaded couplings as an integral element in industries that prioritize performance and sustainability.

Despite their critical role, the true value of stainless steel threaded couplings is often appreciated through real-world experience. Industries such as marine and offshore drilling rely heavily on these materials. For instance, in marine environments where equipment is relentlessly exposed to saltwater, the resilience of stainless steel couplings is not just beneficial but necessary. Companies operating in these sectors have consistently reported improved service life and reduced downtime when opting for high-quality stainless steel fittings. Incorporating stainless steel threaded couplings into a piping system goes beyond functional necessity; it is an investment in system longevity and operational effectiveness. The reflective sheen of stainless steel serves as a silent witness to its steadfast resilience against corrosion and physical stress. For sectors prioritizing sustainability and cost efficiency, these couplings offer an unmatched return on investment by reducing long-term maintenance costs and enhancing system resilience. Accuracy and reliability of information about stainless steel threaded couplings are crucial for making informed decisions. This is where authoritative resources and consultations with seasoned professionals become invaluable. Engineers often rely on detailed technical documentation and case studies to evaluate the performance in specific application scenarios. Trust in data and expert recommendations effectively guides purchasing decisions and strategic planning in using these components. Precision-crafted stainless steel threaded couplings not only fulfill fundamental connection roles but also contribute significantly to the overall integrity of piping systems. Their strategic selection and application align directly with aspirations for enhanced safety, reliability, and efficiency in industrial operations. As environments and technologies evolve, the demand for resilient, versatile, and reliable coupling solutions continues to grow, positioning stainless steel threaded couplings as an integral element in industries that prioritize performance and sustainability.

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products