Feb . 15, 2025 22:27

Back to list

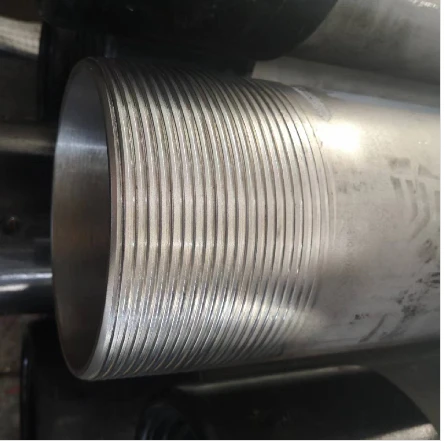

well casing coupling

In the intricate world of oil and gas drilling, the importance of well casing coupling cannot be overstated. This vital component plays a crucial role in maintaining the integrity and safety of well structures. A well casing coupling primarily serves to connect segments of pipe, ensuring a seamless and robust assembly that can withstand the tremendous pressures encountered at various depths.

Trustworthiness is a fundamental consideration when dealing with well casing couplings. Manufacturers who prioritize transparency in their production processes, backed by rigorous testing and quality assurance protocols, typically stand out in this critical industry landscape. Third-party certifications and traceability of materials further cement the credibility of a coupling product, assuring that every piece adheres to the highest benchmarks of safety and performance. Moreover, real-world experience has shown that the longevity and resilience of well casing couplings also depend on proper handling and installation. Training personnel in the correct procedures for coupling alignment, thread lubrication, and torque application can drastically reduce the risk of joint failure, a common cause of operational downtime and costly repairs. The selection and use of well casing couplings transcend merely connecting pipe sections; they encapsulate a holistic understanding of engineering principles, regulatory compliance, and environmental considerations. As the fossil fuel industry pushes the boundaries of exploration, with wells being drilled deeper and in more demanding locations, the role of well casing couplings becomes even more critical. Ultimately, the effectiveness of a well casing coupling is a testament to the integration of engineering excellence, regulatory coherence, and technical innovation. For professionals in the field, staying abreast of the latest advancements in coupling technology and best practices is not just recommended but essential. This proactive approach ensures that operations are not only efficient but also uphold the highest standards of safety and environmental stewardship. In summary, well casing couplings are the unsung heroes of well construction, quietly ensuring the structural integrity and operational efficiency of drilling undertakings around the globe. Through a combination of cutting-edge technology, rigorous standards, and expert application, these components continue to be a cornerstone of modern energy exploration.

Trustworthiness is a fundamental consideration when dealing with well casing couplings. Manufacturers who prioritize transparency in their production processes, backed by rigorous testing and quality assurance protocols, typically stand out in this critical industry landscape. Third-party certifications and traceability of materials further cement the credibility of a coupling product, assuring that every piece adheres to the highest benchmarks of safety and performance. Moreover, real-world experience has shown that the longevity and resilience of well casing couplings also depend on proper handling and installation. Training personnel in the correct procedures for coupling alignment, thread lubrication, and torque application can drastically reduce the risk of joint failure, a common cause of operational downtime and costly repairs. The selection and use of well casing couplings transcend merely connecting pipe sections; they encapsulate a holistic understanding of engineering principles, regulatory compliance, and environmental considerations. As the fossil fuel industry pushes the boundaries of exploration, with wells being drilled deeper and in more demanding locations, the role of well casing couplings becomes even more critical. Ultimately, the effectiveness of a well casing coupling is a testament to the integration of engineering excellence, regulatory coherence, and technical innovation. For professionals in the field, staying abreast of the latest advancements in coupling technology and best practices is not just recommended but essential. This proactive approach ensures that operations are not only efficient but also uphold the highest standards of safety and environmental stewardship. In summary, well casing couplings are the unsung heroes of well construction, quietly ensuring the structural integrity and operational efficiency of drilling undertakings around the globe. Through a combination of cutting-edge technology, rigorous standards, and expert application, these components continue to be a cornerstone of modern energy exploration.

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products