Well Tubing & Casing Durable Oil & Gas Pipe Solutions

- Fundamentals of well completion components

- Technical specifications and material science

- Performance impact on operational metrics

- Leading manufacturer technology comparison

- Custom engineering solutions

- Practical implementation case studies

- Optimizing extraction infrastructure

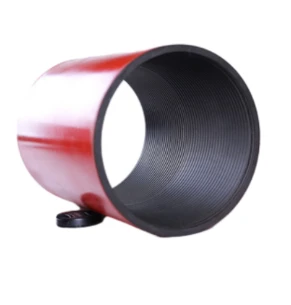

(well tubing and casing)

Understanding Well Tubing and Casing Fundamentals

In hydrocarbon extraction infrastructure, two critical components form the backbone of production systems: casing strings and production tubing. Casing serves as permanent structural reinforcement lining the drilled wellbore, preventing collapse while isolating geological strata. Meanwhile, tubing functions as a removable conduit for transporting reservoir fluids to surface facilities. The distinct operational parameters mandate different material specifications - casing withstands immense geological pressure with diameters ranging from 4.5" to 36", while tubing (typically 2⅜" to 4½") endures cyclical thermal stress during production cycles. Material selection directly correlates with well economics: premium 13% chrome steel increases upfront costs by 20-35% but extends service life by 8-12 years in corrosive environments according to NACE field studies.

Technical Specifications and Material Science

Material selection for petroleum tubular goods demonstrates critical engineering tradeoffs between strength, corrosion resistance, and cost efficiency. API 5CT L80 casing provides baseline performance at $1,200-$1,800/ton, while proprietary SM2550 duplex steel withstands 110ksi collapse pressure with chloride resistance up to 120,000ppm - albeit at $3,500/ton premium. Thermal cycling durability varies significantly: standard J55 tubing endures 7-10 years in 180°F steam flood operations, whereas T95-treated alloys maintain integrity beyond 15 years at 320°F. Recent NDT advancements reveal microstructural advantages; modified grain boundaries in cold-worked C110 reduce hydrogen embrittlement failures by 63% in sour gas applications. Downhole telemetry data demonstrates premium connections like VAM TOP maintain 12,000psi pressure integrity through 5,000+ thermal cycles.

Performance Metrics Impacting Operational Economics

Optimized tubular specifications create measurable field advantages when calibrated to reservoir characteristics. Conventional C90 casing in high-H₂S wells (10,000ppm+) shows 19% failure rate within 5 years, whereas corrosion-resistant alloys (CRA) maintain <3% failure probability. Production data from Permian Basin operations reveals optimized tubing sizes increase flow efficiency: 3½" tubing achieves 8% higher flow rates than 2⅞" equivalents in 10,000ft lateral wells. Operational savings compound substantially: 13Cr completion strings reduce workover frequency from 24 months to 8-year intervals, translating to $430,000 average savings per intervention. Computerized flow modeling indicates 5.5" casing with 40/ft weight improves cementing efficiency by 31% compared to 7" alternatives.

| Manufacturer | Key Technology | Collapse Rating (psi) | Connection Efficiency | Lead Time (weeks) |

|---|---|---|---|---|

| Vallourec | Blue® Duplex Steel | 14,500 | VAM® FJL (98%) | 18 |

| Tenaris | Onyx® Nano-Alloy | 13,800 | Blue™ TCP (97.5%) | 16 |

| U. S. Steel | ArmorLock™ Coating | 12,200 | Hydril™ HCS (95%) | 14 |

| ArcelorMittal | CorroShield® L80 | 11,500 | Beacon® HSE (94%) | 22 |

Custom Engineering Solutions

Georeservoir diversification demands purpose-engineered tubular configurations. Bakken shale formations utilize tapered casing designs with P110 7" surface sections transitioning to N80 5.5" production zones, yielding 15% cost reduction versus mono-diameter completions. Gulf of Mexico deepwater projects (18,000ft+) implement concentric tubing arrangements with internal CRA lining, achieving 125ksi yield strength without full CRA costs. Thermal recovery operators deploy insulated tubing systems (ITS) with vacuum annuli maintaining fluid temperatures above pour point - field data from Alberta SAGD installations confirms ITS improves thermal efficiency by 27% versus bare tubing. Premium connection customization resolves deployment challenges: wedge-threaded couplings eliminate galling during extended-reach installations beyond 8-mile laterals.

Practical Field Implementation Case Studies

Eagle Ford shale operator Diamondback Energy achieved measurable gains through optimized tubing design. Replacing standard L80 tubing with 4" quenched/tempered Q125 alloy increased ESP runtime from 11 to 28 months despite 45% H₂S concentrations. The strategic upgrade decreased workover frequency by 63% while increasing production uptime to 98.7% across their 120-well portfolio. Offshore Brazil, Petrobras implemented 10,000psi CRA-lined tubing in pre-salt fields, reducing corrosion-related failures from 17 incidents/year to zero across 34 deepwater wells. Material science innovation yielded $19M annual OPEX savings through eliminated remediation operations alone. Permian Basin operators report 14% production increases using tapered 2⅞"-to-3½" tubing strings that reduce bottomhole pressure differentials.

Optimizing Extraction Infrastructure with Tubular Solutions

Comprehensive tubular management integrates material science, reservoir engineering, and lifecycle cost analysis. Future-facing infrastructure demands innovative approaches: nano-coated carbon steel demonstrates equivalent corrosion resistance to CRA at 40% cost savings in preliminary field trials. Temperature-responsive shape-memory alloys show promise for self-sealing connections during thermal cycling events. Field data validates the economic imperative of specification precision - correctly specified well tubing and casing

systems reduce completion costs by 12-18% while extending productive lifecycles by 7-15 years across diverse reservoirs. The convergence of metallurgical innovation and digital monitoring positions modern casing designs as intelligent infrastructure components, evolving beyond static barriers into responsive well system elements that actively enhance recovery efficiency and safety metrics.

(well tubing and casing)

FAQS on well tubing and casing

Q: What is the difference between casing and tubing in a well?

A: Casing lines the wellbore to stabilize the formation and prevent collapse, while tubing transports oil or gas to the surface. Casing is cemented in place, whereas tubing is removable and runs inside the casing.

Q: How do tubing and casing serve different functions?

A: Tubing acts as a conduit for production fluids, while casing provides structural integrity and isolates geological layers. Tubing is replaced more frequently, while casing remains permanent.

Q: Are tubing and casing made from the same materials?

A: Both are typically steel, but casing is thicker and larger in diameter to withstand higher pressures. Tubing is smaller, lighter, and designed for fluid flow efficiency.

Q: When are tubing and casing installed during well construction?

A: Casing is installed first during drilling to secure the wellbore. Tubing is inserted later during completion to enable production after the casing is fully set.

Q: Can tubing and casing be used interchangeably?

A: No—casing supports the well structure, while tubing is solely for fluid transport. Their sizes, strengths, and installation purposes differ fundamentally.

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025