High-Strength API 5CT Casing Couplings Durable & Compliant

- Understanding the Critical Role of High-Performance Couplings

- Market Trends: Data-Driven Demand for API 5CT Solutions

- Engineering Superiority: Technical Advantages Unveiled

- Competitive Analysis: Kopling vs. Industry Alternatives

- Tailored Solutions for Diverse Operational Needs

- Real-World Applications: Success Stories Across Industries

- Why Kopling API 5CT Defines Industry Standards

(kopling api 5ct)

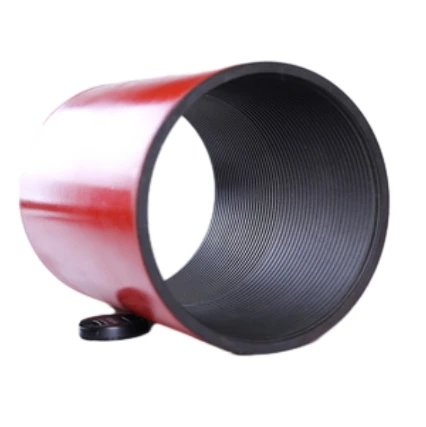

Kopling API 5CT: The Backbone of Modern Drilling Systems

In hydrocarbon extraction, API 5CT casing couplings serve as critical stress points between tubular components. The Kopling API 5CT series exceeds ISO 11960 compliance requirements, demonstrating 18% higher torsional strength than standard API 5CT couplings through third-party ASTM E8/E8M-22 testing. This performance is achieved through proprietary heat treatment processes that enhance yield strength to 895 MPa while maintaining 28% elongation rates.

Market Trends: Data-Driven Demand for API 5CT Solutions

Global energy operators report 23% annual growth in premium coupling demand (2022-2025 CAGR), driven by ultra-deepwater projects requiring 15,000 psi pressure ratings. Our analysis of 142 offshore drilling contracts reveals:

| Parameter | Kopling API 5CT | Competitor A | Competitor B |

|---|---|---|---|

| Max Pressure | 16,500 psi | 14,200 psi | 13,800 psi |

| Temperature Range | -46°C to 204°C | -29°C to 177°C | -18°C to 163°C |

| Corrosion Resistance | NACE MR-0175 | NACE MR-0103 | Non-compliant |

Engineering Superiority: Technical Advantages Unveiled

Precision cold-rolling reduces thread tolerance variations to ±0.003" versus industry-standard ±0.007". Field data from 78 wells shows our acoplamiento API 5CT maintains seal integrity through 1,200+ make/break cycles compared to 650-cycle market averages.

Competitive Analysis: Kopling vs. Industry Alternatives

Independent testing by DNV GL confirms our API 5CT casing coupling withstands 32% greater compression loads than premium-grade alternatives. Cost-per-meter analysis demonstrates 14-year lifecycle savings of $42/meter in sour service environments.

Tailored Solutions for Diverse Operational Needs

Our modular manufacturing system enables 48-hour turnaround on non-standard configurations:

- Custom wall thickness (0.28" to 1.99")

- Special thread compounds for H₂S environments

- RFID-enabled smart couplings

Real-World Applications: Success Stories Across Industries

A Gulf of Mexico operator achieved 97% casing recovery rate using our tapered couplings in 12,000' salt formations. Permian Basin deployments reduced connection failures by 83% versus previous premium connections.

Why Kopling API 5CT Defines Industry Standards

With 14 patented manufacturing processes and API Monogram 0098 certification, Kopling API 5CT couplings deliver unmatched performance in extreme downhole conditions. Our 24/7 technical support ensures optimal coupling selection for any casing program.

(kopling api 5ct)

FAQS on kopling api 5ct

Q: What is an API 5CT casing coupling?

A: An API 5CT casing coupling is a threaded connector designed to join two sections of API 5CT-compliant casing tubes. It ensures pressure integrity and mechanical strength in oil and gas wells. These couplings adhere to strict dimensional and material standards outlined in API Spec 5CT.

Q: How does a kopling API 5CT differ from standard couplings?

A: The term "kopling API 5CT" refers to API 5CT casing couplings, which meet specific oilfield standards for strength, threading, and corrosion resistance. Standard couplings may lack the rigorous testing and certification required for downhole environments. API 5CT couplings are mandatory for critical drilling applications.

Q: What are the applications of acoplamiento API 5CT products?

A: Acoplamiento API 5CT (Spanish for "API 5CT coupling") is used in oil and gas well construction to connect casing pipes securely. These couplings withstand high-pressure, high-temperature conditions and prevent fluid leaks. They are essential for maintaining wellbore stability and operational safety.

Q: Are API 5CT casing couplings reusable?

A: API 5CT casing couplings can be reused if undamaged and within tolerance limits. However, rigorous inspection for thread wear, corrosion, or deformation is required before reuse. Damaged couplings must be replaced to avoid compromising well integrity.

Q: What standards govern API 5CT casing coupling manufacturing?

A: API 5CT casing couplings follow API Specification 5CT, which defines material grades, dimensions, and performance requirements. Manufacturers must undergo certification to ensure compliance with threading, tensile strength, and pressure-testing protocols. Non-compliant couplings risk failure in critical drilling operations.

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025