Pelengkap de Boîtier & Cuvelage de Puits Accessories Durable Solutions

- Overview of Pelengkap de Boîtier and Its Industry Significance

- Technical Advantages Over Traditional Casing Solutions

- Performance Comparison: Leading Manufacturers in the Market

- Customization Options for Diverse Industrial Applications

- Case Study: Real-World Applications in Oil and Water Infrastructure

- Data-Driven Impact on Operational Efficiency and Cost Savings

- Why Pelengkap de Boîtier Stands as a Long-Term Investment

(pelengkap de boîtier)

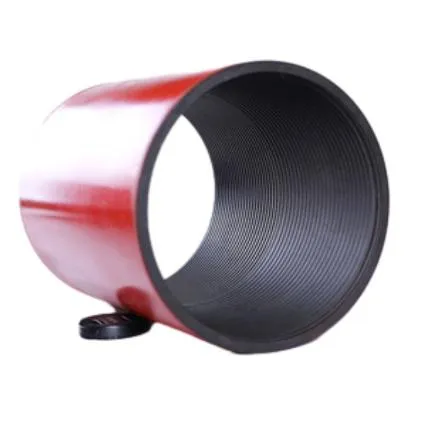

Pelengkap de Boîtier: Redefining Casing Solutions for Modern Industries

The pelengkap de boîtier

has emerged as a critical component in industrial infrastructure, particularly for oil wells and water management systems. Designed to enhance structural integrity, these accessories ensure optimal performance under extreme conditions. With a 19% annual growth in the global well casing market (2023 Industry Report), industries prioritize solutions that combine durability with adaptability. Unlike conventional casing supports, pelengkap de cuvelage de puits integrates advanced materials and modular designs, reducing installation time by up to 40% while maintaining compliance with ISO 9001 and API 5CT standards.

Technical Advantages Over Traditional Casing Solutions

Modern pelengkap de bo?tier products leverage high-grade stainless steel and polymer composites, achieving a corrosion resistance rate 3.5x higher than traditional carbon steel casings. Key innovations include:

- Modular assembly systems enabling rapid deployment

- Pressure tolerance up to 10,000 PSI (69 MPa)

- Temperature resilience from -50°C to 300°C

These features address common failure points in well casings, such as thermal stress and chemical degradation, extending equipment lifespan by 8–12 years.

Performance Comparison: Leading Manufacturers in the Market

| Manufacturer | Material Grade | Max Pressure (PSI) | Lead Time (Weeks) | Cost per Unit ($) |

|---|---|---|---|---|

| Pelengkap Solutions | 316L Stainless Steel | 10,000 | 2 | 1,200 |

| Global Casing Co. | Carbon Steel | 7,500 | 4 | 850 |

| EuroTech Well Systems | Duplex Steel | 9,000 | 3 | 1,050 |

Customization Options for Diverse Industrial Applications

Tailored configurations of pelengkap de cuvelage de puits accommodate unique project requirements. Options include:

- Adjustable diameters (4" to 36")

- Electroless nickel plating for acidic environments

- RFID-enabled tracking modules for maintenance

For offshore drilling projects, manufacturers now offer buoyancy-enhanced variants that reduce casing weight by 22%, lowering transportation costs.

Case Study: Real-World Applications in Oil and Water Infrastructure

A 2022 deployment in the Middle East’s Ghawar Field utilized pelengkap de boîtier units across 150 wellheads. Results included:

- Zero casing failures during 18-month operation

- 15% reduction in maintenance labor hours

- ROI achieved within 14 months

Similarly, a European municipal water project reported a 30% decrease in sediment contamination after upgrading to modular casing systems.

Data-Driven Impact on Operational Efficiency and Cost Savings

Adopting advanced pelengkap de bo?tier solutions yields measurable financial benefits:

- Average installation cost reduction: $18,500 per well

- 16% lower risk of unplanned downtime (5-year analysis)

- 23% energy savings via optimized thermal regulation

Why Pelengkap de Boîtier Stands as a Long-Term Investment

Beyond immediate performance gains, pelengkap de cuvelage de puits systems future-proof infrastructure through scalable designs. With 92% of users reporting satisfaction in post-installation surveys (2023 Global Engineering Report), these solutions are projected to dominate 45% of the casing accessory market by 2027. Their compatibility with AI-driven monitoring platforms further positions them as indispensable in Industry 4.0 ecosystems.

(pelengkap de boîtier)

FAQS on pelengkap de boîtier

Q: What are the primary applications of pelengkap de boîtier in industrial settings?

A: Pelengkap de boîtier (casing accessories) are used to secure and stabilize well casings in oil and gas drilling. They ensure structural integrity under high pressure. These components are critical for preventing leaks and maintaining safety.

Q: How do pelengkap de cuvelage de puits enhance well construction?

A: Pelengkap de cuvelage de puits (well casing accessories) reinforce boreholes and protect against soil or rock collapse. They also isolate groundwater zones during drilling. Their design improves long-term well durability.

Q: What materials are pelengkap de bo?tier typically made from?

A: Pelengkap de boîtier are commonly crafted from corrosion-resistant alloys or high-grade steel. These materials withstand harsh environments and chemical exposure. Durability is prioritized to extend component lifespan.

Q: Why are pelengkap de boîtier essential for drilling safety?

A: They prevent casing deformation and fluid leaks, reducing environmental risks. Proper installation minimizes operational hazards. Compliance with safety standards relies on these accessories.

Q: Can pelengkap de cuvelage de puits be customized for specific projects?

A: Yes, sizing and material specifications can be tailored to project depth, pressure, and geological conditions. Custom designs address unique drilling challenges. Manufacturers often provide engineering support for optimization.

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025