Feb . 19, 2025 09:33

Back to list

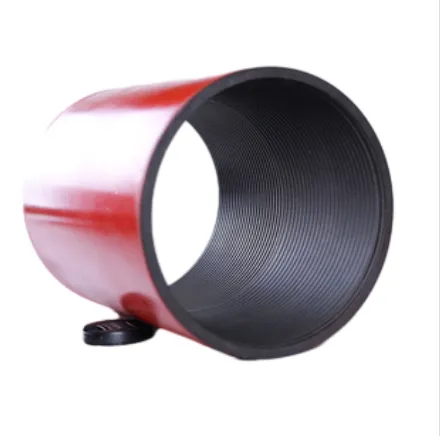

tubing crossover

Tubing crossovers play a crucial role in the oil and gas industry by ensuring compatibility and seamless connections between different tubing sizes or types. As the global energy sector continues to explore deeper reservoirs, the demand for effective and reliable tubing crossovers has surged. To truly understand the significance of these components, it is essential to delve into the intricacies of their application, engineering, and benefits. Rich experience from industry professionals further highlights the indispensable nature of tubing crossovers in modern extractive efforts.

Trustworthiness stems from real-world application and results. Case studies from leading oil exploration companies underscore the reliability of advanced tubing crossovers in reducing downtime and maintenance costs. These components not only enhance the integrity of the pipeline systems but also significantly boost overall productivity by ensuring a smooth, uninterrupted operation. Moreover, their role in facilitating transitions in downhole environments ensures that extraction processes remain efficient and cost-effective, even in the face of challenging conditions. A practical example of tubing crossovers in action involves deepwater drilling, where extreme undersea pressures and temperatures pose formidable challenges. By employing meticulously designed crossovers, engineers have successfully maintained the integrity of the extraction process without compromising safety or efficiency. Such deployment illustrates the critical nature of crossovers and their ability to overcome formidable barriers in the most hostile of environments. The effectiveness of tubing crossovers also extends to cost management in large-scale projects. By minimizing risks associated with leaks or equipment damage, crossovers contribute to more predictable budgeting and resource allocation. This aspect is particularly important in the context of volatile crude oil prices, where inefficiencies can significantly impact a project’s bottom line. In summary, the role of tubing crossovers is indispensable in the modern landscape of oil and gas extraction. Their ability to provide versatility, robustness, and reliability is backed by extensive expertise from industry leaders, rigorous engineering processes, and practical application in challenging scenarios. As the energy industry continues to be a linchpin of modern economies, the unwavering reliability of tubing crossovers ensures that energy channels remain open, productive, and safe. For any stakeholder involved in this sector, recognizing the indispensable nature of these modest yet mighty components is a step towards ensuring long-term success and sustainability in energy exploitation efforts.

Trustworthiness stems from real-world application and results. Case studies from leading oil exploration companies underscore the reliability of advanced tubing crossovers in reducing downtime and maintenance costs. These components not only enhance the integrity of the pipeline systems but also significantly boost overall productivity by ensuring a smooth, uninterrupted operation. Moreover, their role in facilitating transitions in downhole environments ensures that extraction processes remain efficient and cost-effective, even in the face of challenging conditions. A practical example of tubing crossovers in action involves deepwater drilling, where extreme undersea pressures and temperatures pose formidable challenges. By employing meticulously designed crossovers, engineers have successfully maintained the integrity of the extraction process without compromising safety or efficiency. Such deployment illustrates the critical nature of crossovers and their ability to overcome formidable barriers in the most hostile of environments. The effectiveness of tubing crossovers also extends to cost management in large-scale projects. By minimizing risks associated with leaks or equipment damage, crossovers contribute to more predictable budgeting and resource allocation. This aspect is particularly important in the context of volatile crude oil prices, where inefficiencies can significantly impact a project’s bottom line. In summary, the role of tubing crossovers is indispensable in the modern landscape of oil and gas extraction. Their ability to provide versatility, robustness, and reliability is backed by extensive expertise from industry leaders, rigorous engineering processes, and practical application in challenging scenarios. As the energy industry continues to be a linchpin of modern economies, the unwavering reliability of tubing crossovers ensures that energy channels remain open, productive, and safe. For any stakeholder involved in this sector, recognizing the indispensable nature of these modest yet mighty components is a step towards ensuring long-term success and sustainability in energy exploitation efforts.

Next:

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products