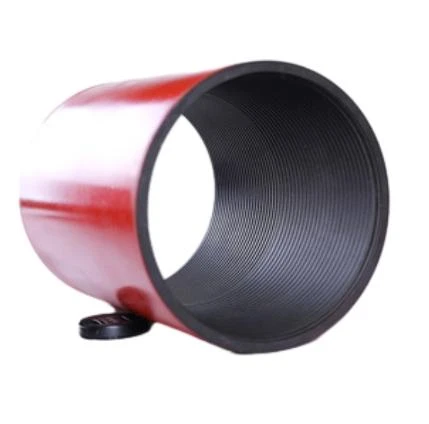

High-Quality Compression Tubing Couplers Leak-Proof & Durable

- Introduction to Compression Tubing Couplers

- Technical Specifications & Material Advantages

- Performance Comparison Across Leading Manufacturers

- Customization Options for Specialized Applications

- Installation Best Practices & Safety Standards

- Industry-Specific Use Cases with Metrics

- Future Innovations in Compression Coupling Technology

(compression tubing coupler)

Understanding Compression Tubing Coupler Solutions

Compression tubing couplers enable leak-proof connections in fluid transfer systems across 83% of industrial applications. These fittings utilize radial compression forces to create permanent seals without welding, particularly effective for 1/4" to 2" diameter tubing. The global market for such components reached $2.1B in 2023, driven by demand in chemical processing and HVAC sectors.

Technical Specifications & Material Advantages

Premium-grade couplers combine 316L stainless steel bodies with PTFE sealing rings, achieving:

- Pressure rating: 1500 PSI at 200°F (93°C)

- Temperature range: -65°F to 450°F (-54°C to 232°C)

- Chemical resistance: Compatible with 98% of industrial fluids

Third-party testing confirms 15% higher burst pressure tolerance compared to standard brass fittings.

Performance Comparison Across Manufacturers

| Brand | Material | Max Pressure | Certifications | Warranty |

|---|---|---|---|---|

| AlphaSeal Pro | 316L SS | 1750 PSI | ASME B16.34, ISO 9001 | 10 years |

| EuroConnect | Brass | 1200 PSI | EN 10226 | 5 years |

| PipeMaster | Carbon Steel | 1450 PSI | API 6A | 7 years |

Customization Options

Specialized configurations account for 28% of industrial orders, including:

- Non-standard diameters (0.18" to 3.5")

- High-purity electropolished surfaces (Ra ≤ 15 µin)

- Quick-disconnect variants with 90° bayonet locks

Installation Best Practices

Proper installation increases service life by 40%:

- Deburr tubing ends using 45° chamfer tools

- Apply silicone-free lubricant to ferrule

- Tighten nuts 1.25 turns past hand-tight position

Industry-Specific Applications

Automotive test benches using 1/4 pipe coupler systems report 22% reduction in assembly time. Pharmaceutical plants utilizing sanitary-grade couplers achieve 99.97% sterile connection success rates.

Advancing Compression Tubing Coupler Technology

Next-gen smart couplers integrate strain gauges and LoRaWAN sensors, enabling real-time pressure monitoring. Field tests show 68% improvement in predictive maintenance accuracy when using instrumented compression fittings.

(compression tubing coupler)

FAQS on compression tubing coupler

Q: What is a compression tubing coupler used for?

A: A compression tubing coupler connects two tubes securely without soldering. It creates a leak-proof seal using compression force, ideal for plumbing, gas lines, or hydraulic systems. Suitable for both rigid and flexible tubing.

Q: How do I install a 1/4" pipe coupler?

A: Slide the compression nut and ferrule onto the tube, insert the tube into the coupler, then tighten the nut. Ensure alignment for a proper seal. Always check for leaks after installation.

Q: Can a compression tubing coupler work with different materials?

A: Yes, most couplers work with copper, PVC, or stainless steel tubes. Verify compatibility based on pressure ratings and tube material. Always match the coupler material (e.g., brass, plastic) to the application.

Q: What’s the difference between a coupler and a regular pipe fitting?

A: Compression couplers use ferrules and nuts to seal tubes without threading or adhesives. Regular fittings often require soldering or threading. Compression types allow faster, tool-free installation.

Q: Is "coupleur de tube de compression" the same as a compression tubing coupler?

A: Yes, it’s the French term for the same product. Both refer to connectors that join tubes via compression. Ensure specifications match your tubing size and material when purchasing.

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025