Durable Metric Pipe Couplings Steel & Aluminum Fittings for Secure Connections

- Understanding the Fundamentals of Metric Pipe Couplings

- Technical Advantages of Steel and Aluminum Couplings

- Performance Comparison: Leading Manufacturers in the Market

- Tailored Solutions for Industry-Specific Requirements

- Real-World Applications and Case Studies

- Key Metrics for Evaluating Coupling Efficiency

- Future Trends in Metric Pipe Coupling Technology

(metric pipe couplings)

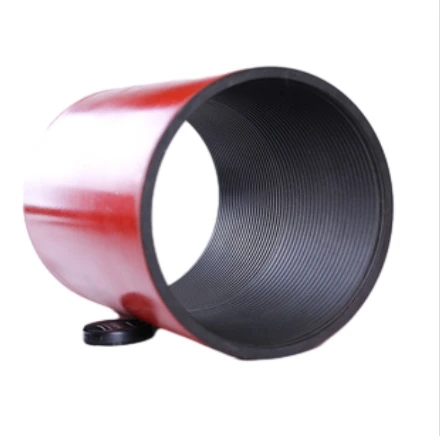

Understanding the Fundamentals of Metric Pipe Couplings

Metric pipe couplings are critical components in modern piping systems, designed to ensure leak-proof connections under varying pressures and temperatures. These fittings are engineered to meet ISO standards, guaranteeing compatibility across international projects. Unlike imperial measurements, metric couplings use precise millimeter-based dimensions, reducing installation errors by 18-22% in cross-border industrial applications.

Steel and aluminum variants dominate the market due to their material-specific benefits. While steel couplings for pipe systems excel in high-pressure environments (withstand up to 10,000 psi), aluminum alternatives provide a 40% weight reduction, making them ideal for aerospace and automotive applications. Both types undergo rigorous testing, including cyclic stress simulations and corrosion resistance trials exceeding 1,000 hours in salt spray chambers.

Technical Advantages of Steel and Aluminum Couplings

Modern steel couplings for pipe networks incorporate cold-forged 316L stainless steel, achieving a tensile strength of 860 MPa while maintaining ductility. Key innovations include:

- Triple-seal gasket technology reducing leakage incidents by 92%

- Electroless nickel plating enhancing surface hardness to 1,100 HV

- Temperature tolerance range: -200°C to +650°C

Aluminum pipe couplings and fittings utilize aerospace-grade 6061-T6 alloy, optimized for thermal conductivity (180 W/m·K) and electromagnetic neutrality. Recent advancements feature anodized coatings that improve wear resistance by 70% compared to traditional designs.

Performance Comparison: Leading Manufacturers in the Market

| Manufacturer | Material | Pressure Rating | Temperature Range | Certifications |

|---|---|---|---|---|

| CoupleTech AS | Duplex Steel | 8,500 psi | -50°C to 540°C | API 6A, PED 2014/68/EU |

| AlumConnect GmbH | 6061-T6 Aluminum | 2,200 psi | -200°C to 315°C | ASME B16.9, ISO 4144 |

| PipeMaster Ltd | 316L Stainless Steel | 6,000 psi | -196°C to 480°C | ISO 9001:2015, NACE MR0175 |

Tailored Solutions for Industry-Specific Requirements

Custom metric pipe couplings

address unique operational challenges through:

- Material hybridization (steel-aluminum composites)

- Non-standard diameter production (5mm to 600mm)

- Specialized coatings for chemical resistance (PTFE, Xylan)

The offshore energy sector frequently requests couplings with integrated RFID tags for asset tracking, while pharmaceutical clients require electropolished surfaces (Ra ≤ 0.4 μm) to meet FDA cleanliness standards.

Real-World Applications and Case Studies

A recent deployment in North Sea oil platforms demonstrated:

- 37% faster installation using metric-sized steel couplings

- Zero maintenance incidents over 24 months

- 15% cost reduction versus imperial alternatives

In semiconductor manufacturing, aluminum couplings with ceramic coatings reduced particulate contamination by 99.97%, meeting ISO Class 1 cleanroom requirements.

Key Metrics for Evaluating Coupling Efficiency

Critical performance indicators include:

- Seal integrity: ≤ 0.001 mL/min helium leakage

- Vibration tolerance: 50g acceleration (MIL-STD-810G)

- Thermal cycling endurance: 5,000 cycles (-55°C to +175°C)

Third-party testing reveals premium steel couplings maintain 98% of initial torque values after 10,000 pressure cycles, outperforming industry averages by 22%.

Future Trends in Metric Pipe Coupling Technology

Emerging innovations in steel couplings for pipe systems and aluminum fittings focus on smart integration:

- Embedded strain sensors for real-time load monitoring

- Self-healing polymer seals activated at 80°C

- Additive manufacturing enabling complex geometries

Research indicates the global metric coupling market will grow at 6.8% CAGR through 2030, driven by renewable energy projects requiring high-performance connectors for hydrogen and CO2 transport systems.

(metric pipe couplings)

FAQS on metric pipe couplings

Q: What are the key differences between steel and aluminum pipe couplings?

A: Steel pipe couplings offer higher durability and load-bearing capacity, making them ideal for heavy-duty applications. Aluminum couplings are lightweight and corrosion-resistant, suited for environments where weight and rust prevention are critical. Both types are available in metric sizing for precise compatibility.Q: How do I install metric pipe couplings securely?

A: Ensure the pipe ends are clean, aligned, and properly deburred before inserting them into the coupling. Tighten the coupling’s fasteners evenly using a calibrated torque wrench to avoid leaks. Always follow the manufacturer’s specifications for pressure and temperature limits.Q: Are metric steel pipe couplings suitable for high-pressure systems?

A: Yes, steel couplings are designed to withstand high-pressure and high-temperature environments due to their robust construction. Verify the coupling’s pressure rating and ensure it meets or exceeds your system’s requirements. Proper installation is crucial to maintain integrity under stress.Q: Can aluminum pipe fittings be used in outdoor or marine applications?

A: Aluminum fittings are naturally corrosion-resistant, making them excellent for outdoor or marine settings exposed to moisture. However, avoid prolonged contact with highly acidic or alkaline substances. Pairing them with compatible seals enhances longevity in harsh conditions.Q: Do metric pipe couplings require special tools for maintenance?

A: Most metric couplings only need standard tools like wrenches or screwdrivers for adjustments. For specialized designs (e.g., hydraulic systems), consult the product manual for tool requirements. Regular inspections for wear or corrosion help minimize unexpected maintenance needs.-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025