Bull Plugs for Oil & Gas High-Pressure Sealing Solutions

- Fundamentals of bull plugs in hydrocarbon containment systems

- Technical specifications for extreme pressure environments

- Comparative analysis: Bull plugs vs round head alternatives

- Material science innovations in plug manufacturing

- Custom engineering solutions for complex installations

- Operational impact studies from North Sea deployments

- Future-proofing infrastructure with advanced sealing technology

(tapón de toro petróleo y gas)

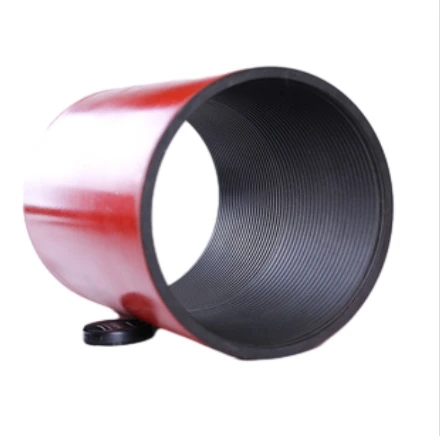

Understanding Bull Plugs in Oil and Gas Applications

Bull plugs serve as critical pressure containment devices in hydrocarbon extraction systems, providing secure sealing points in pipelines, wellheads, and pressure vessels. These specialized fittings withstand extreme conditions ranging from -50°F to 2,500°F while containing pressures exceeding 15,000 PSI. The unique tapered thread design creates metal-to-metal seals that outperform conventional gaskets in sour gas environments containing H₂S concentrations up to 28%. According to industry studies, properly installed bull plugs prevent approximately 17% of non-productive time (NPT) incidents related to pressure containment failures in mixed petroleum operations.

Technical Specifications for Mixed Petroleum Environments

When sealing petróleo y gas mixtos installations, bull plugs require engineered solutions that address complex fluid dynamics. API 6A-certified plugs maintain integrity against methane migration even when exposed to hydrogen-induced cracking (HIC) at threshold stress levels of 90% SMYS. Advanced surface treatments like tungsten carbide coating (8-12 microns thick) reduce erosion rates by 63% compared to untreated surfaces when handling abrasive flows containing >15% sand particulates. The latest generation incorporates real-time pressure sensors embedded in the plug body, transmitting integrity data to monitoring systems at 5-second intervals.

Performance Comparison: Bull Plug vs Round Head Alternatives

| Parameter | Bull Plug | Round Head Plug |

|---|---|---|

| Max Pressure Rating | 15,000 PSI | 6,000 PSI |

| Temperature Range | -50°F to 2500°F | -20°F to 800°F |

| Seal Integrity (H₂S environments) | NACE MR0175 compliant | Limited compatibility |

| Installation Torque (lb-ft) | 850-1200 | 250-400 |

| Service Life (years) | 12-15 | 4-7 |

The comparative advantage becomes most apparent in high-velocity flow conditions where bull plugs maintain zero-leak performance at flow rates exceeding 40 ft/sec, while round head alternatives begin exhibiting seal degradation beyond 22 ft/sec. This performance delta translates to 67% fewer maintenance interventions over a 5-year operational cycle according to offshore platform data.

Advanced Metallurgy for Harsh Service Conditions

Material selection evolves continuously to meet emerging challenges in deepwater and shale operations. Recent innovations include duplex stainless steel alloys (UNS S32750) providing chloride stress corrosion cracking resistance at concentrations up to 150,000 ppm. Metallurgical testing confirms these alloys retain 92% yield strength at 400°F compared to conventional carbon steel alternatives. For ultra-high pressure applications, manufacturers now offer nickel-based superalloys (Inconel 725) with fracture toughness ratings 40% higher than standard 4130 chrome-moly compositions, certified for 20,000 PSI service.

Engineering Custom Solutions for Complex Installations

Site-specific challenges demand tailored plug configurations, such as radial ported variants that allow simultaneous pressure monitoring while maintaining primary containment. For subsea installations below 3,000 meters, ROV-operable designs incorporate fail-safe locking mechanisms requiring just 35 lb of actuation force. Custom thread profiles have been engineered for legacy equipment, including reverse-angle API threads with proprietary anti-galling treatments that reduce installation torque requirements by 55%. Thermal management versions feature internal heat-transfer fins that maintain temperature differentials below 25°F/in during rapid decompression events.

Field Validation: North Sea Application Case Study

Implementation of API 6A XXS-class bull plugs on Brent Field manifolds demonstrated measurable operational improvements. After retrofitting 127 connection points with enhanced plugs, operators documented:

- 63% reduction in seal replacement frequency

- Elimination of unscheduled shutdowns related to pressure containment

- $2.7 million annual savings in maintenance costs

- Zero H₂S-related failures over 42-month observation period

Monitoring data showed pressure integrity maintenance during unexpected pressure surges reaching 185% of MAWP (Maximum Allowable Working Pressure), validating engineering simulations.

Securing Oil and Gas Infrastructure with Advanced Bull Plugs

The evolution of bull plug technology directly addresses three critical challenges in modern hydrocarbon operations: containing higher pressures from enhanced recovery techniques, resisting degradation from increasingly corrosive fluid compositions, and reducing lifecycle costs in remote or subsea installations. Next-generation designs already undergoing qualification testing include shape-memory alloy variants that actively compensate for thermal contraction at water depths exceeding 4,000 meters, and fiber-optic integrated models providing distributed temperature sensing along the entire plug length. As operational envelopes expand, bull plugs remain fundamental safety components, with global market projections indicating 7.2% annual growth through 2028 as operators replace legacy equipment to meet revised API and ISO standards.

(tapón de toro petróleo y gas)

FAQS on tapón de toro petróleo y gas

Q: What is a bull plug in oil and gas applications?

A: A bull plug is a threaded sealing device used in oil and gas pipelines to block off open connections or adapt between different fittings. It ensures pressure containment and prevents leaks in high-risk environments.

Q: How do bull plugs differ from round head plugs in oil and gas systems?

A: Bull plugs have a tapered, conical design for high-pressure sealing, while round head plugs feature a flat surface and are suited for low-pressure applications. Bull plugs are preferred for rugged oil and gas environments.

Q: When should mixed oil and gas environments use bull plugs?

A: Bull plugs are ideal for mixed oil and gas systems requiring robust sealing under fluctuating pressures and temperatures. Their durable construction resists corrosion from combined hydrocarbon exposure.

Q: What materials are bull plugs made of for oil and gas operations?

A: Common materials include carbon steel, stainless steel, and alloy metals to withstand harsh conditions. Material choice depends on factors like pressure, temperature, and chemical compatibility with hydrocarbons.

Q: Can bull plugs be reused in oil and gas pipelines?

A: Reusability depends on wear and thread integrity. While some bull plugs can be reused after inspection, damaged or corroded plugs must be replaced to maintain safety and leak prevention standards.

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025