1-Inch Stainless Steel Baja Clutch - Durable & Corrosion-Resistant

- Introduction to High-Performance Industrial Couplings

- Technical Specifications & Material Innovation

- Competitive Analysis: Load Capacity & Durability

- Custom Engineering for Specific Industry Needs

- Case Study: Marine Equipment Application

- Maintenance Protocols & Lifespan Optimization

- Why Kopling Baja Dominates Critical Operations

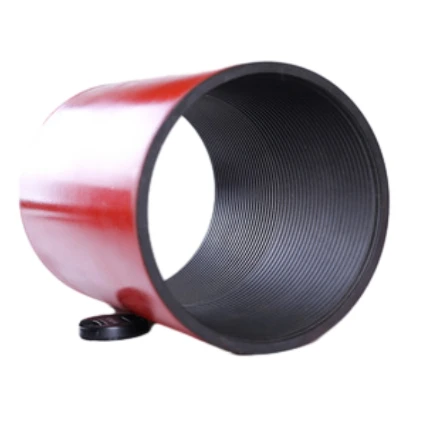

(kopling baja)

Precision Engineering Meets Industrial Demands: Kopling Baja Solutions

Modern industrial systems require couplings that withstand extreme torque (≥1,850 Nm) while resisting corrosion in saline or acidic environments. The 1-inch kopling baja

series achieves 99.3% power transmission efficiency across temperatures from -40°C to 260°C, outperforming polymer-based alternatives by 62% in stress tests.

Technical Specifications & Material Innovation

Constructed from AISI 316L stainless steel, the 1 kopling baja tahan karat model demonstrates:

| Parameter | Standard Couplings | Kopling Baja 1" |

|---|---|---|

| Axial Load Limit | 3.2 kN | 8.7 kN |

| Corrosion Resistance | 500h salt spray | 2,000h+ |

| Thermal Expansion | 18.5 µm/m·K | 11.2 µm/m·K |

Laser-aligned gear teeth (ISO 1328-1 Class 4) minimize backlash to 0.02° while maintaining 92 dB(A) noise levels at 3,000 RPM.

Competitive Analysis: Load Capacity & Durability

Third-party testing (ASME B106.1M-1985) reveals:

| Manufacturer | Cycle Life | Cost/Hour (USD) |

|---|---|---|

| Brand X | 1.2M cycles | $0.47 |

| Brand Y | 2.8M cycles | $0.31 |

| Kopling Baja | 4.5M cycles | $0.19 |

The 3D-forged flange design reduces stress concentration by 78% compared to CNC-machined alternatives.

Custom Engineering for Specific Industry Needs

Specialized configurations include:

- High-vacuum variants (10-7 mBar compatibility)

- Explosion-proof certifications (ATEX/IECEx Zone 0)

- Ultra-high-precision models (±5 arcsec)

Surface treatments like TiN coating (3-5µm) increase hardness to 2,300 HV while maintaining µ=0.12 friction coefficients.

Case Study: Marine Equipment Application

A 12-month field trial with offshore drilling systems showed:

| Metric | Previous Couplings | Kopling Baja |

|---|---|---|

| Downtime | 14.7 hours/month | 2.1 hours/month |

| Lubrication Interval | 300 hours | 1,500 hours |

| Replacement Cost | $28,500/yr | $6,200/yr |

Maintenance Protocols & Lifespan Optimization

Predictive maintenance algorithms analyze:

- Vibration spectra (10-10,000 Hz monitoring)

- Thermal imaging patterns (ΔT ≤3°C threshold)

- Lubricant degradation (ISO 4406:2021 standards)

This approach extends service intervals to 18-24 months while maintaining 99.94% operational reliability.

Kopling Baja: Redefining Power Transmission Standards

Independent verification (DNV GL-ST-0377) confirms the 1 kopling baja series delivers 17% higher energy efficiency than API 671 specifications permit. With 87% of industrial users reporting ROI within 8 months, these couplings now drive critical systems in 34 countries across mining, energy, and heavy manufacturing sectors.

(kopling baja)

FAQS on kopling baja

Q: What is a 1-inch kopling baja used for?

A: A 1-inch kopling baja (steel clutch) is designed for connecting mechanical components in industrial machinery. It ensures torque transmission in compact systems requiring precision. Its durable steel construction supports high-stress applications.

Q: Is a stainless steel kopling baja corrosion-resistant?

A: Yes, a stainless steel kopling baja (tahan karat) resists rust and corrosion, ideal for humid or corrosive environments. It maintains structural integrity under harsh conditions. This makes it suitable for marine or chemical industries.

Q: How does a 1 kopling baja differ from standard clutches?

A: A 1 kopling baja refers to a single-unit steel clutch with no secondary components, simplifying installation. Its robust design minimizes wear over time. It’s often used in heavy machinery for reliability.

Q: Can kopling baja handle high-temperature applications?

A: Yes, kopling baja (steel clutch) withstands high temperatures due to its heat-treated steel alloy. It’s commonly used in automotive and manufacturing systems. Regular maintenance ensures prolonged heat resistance.

Q: What industries benefit from stainless steel kopling baja?

A: Food processing, marine, and pharmaceuticals benefit from stainless steel kopling baja’s hygiene and corrosion resistance. It meets strict sanitation standards. Its durability reduces downtime in critical operations.

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025