Feb . 15, 2025 22:07

Back to list

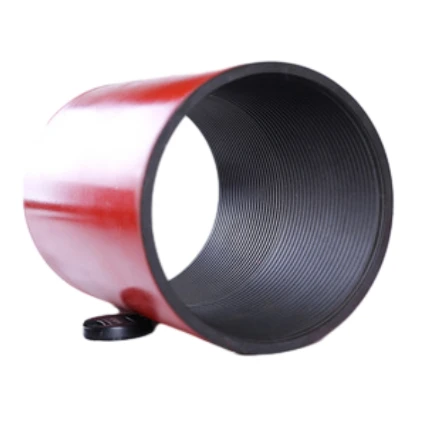

finished casing coupling

In the dynamic world of oil and gas exploration, maintaining the structural integrity of wells is paramount. The finished casing coupling is a critical product in this sector, serving as both a protector and a connector for the casing pipes that line wellbores. This essential component is designed to secure and reinforce the casing joints, preventing leakage and ensuring the safe transportation of oil and gas from deep underground reservoirs to the surface.

Trustworthiness is further established through case studies and field experiences shared by companies that have successfully implemented these coupling solutions. Testimonials from major exploration and production operators highlight the decreased incidence of casing failures and enhanced operational efficiency achieved through the use of high-quality finished casing couplings. For instance, a notable oil company recorded a 20% increase in drill time efficiency after switching to a proprietary coupling design renowned for its durability and sealing capability. With the ongoing exploration of deepwater and unconventional resources, the demand for robust casing solutions has never been higher. The finished casing coupling plays a pivotal role in enabling the energy industry to meet global demands safely and sustainably. Its development continues to evolve, incorporating smart technologies and coatings that offer real-time monitoring and additional layers of protection against environmental challenges. In conclusion, the finished casing coupling is more than just a mechanical component; it’s a linchpin that ensures the safety and efficacy of oil and gas extraction. Selecting the right coupling is a critical decision for any operation, influencing both the short-term success and long-term integrity of production wells. As the industry moves towards more challenging environments and stricter regulations, investing in superior coupling technology reflects a commitment to excellence and safety in energy production.

Trustworthiness is further established through case studies and field experiences shared by companies that have successfully implemented these coupling solutions. Testimonials from major exploration and production operators highlight the decreased incidence of casing failures and enhanced operational efficiency achieved through the use of high-quality finished casing couplings. For instance, a notable oil company recorded a 20% increase in drill time efficiency after switching to a proprietary coupling design renowned for its durability and sealing capability. With the ongoing exploration of deepwater and unconventional resources, the demand for robust casing solutions has never been higher. The finished casing coupling plays a pivotal role in enabling the energy industry to meet global demands safely and sustainably. Its development continues to evolve, incorporating smart technologies and coatings that offer real-time monitoring and additional layers of protection against environmental challenges. In conclusion, the finished casing coupling is more than just a mechanical component; it’s a linchpin that ensures the safety and efficacy of oil and gas extraction. Selecting the right coupling is a critical decision for any operation, influencing both the short-term success and long-term integrity of production wells. As the industry moves towards more challenging environments and stricter regulations, investing in superior coupling technology reflects a commitment to excellence and safety in energy production.

Next:

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products