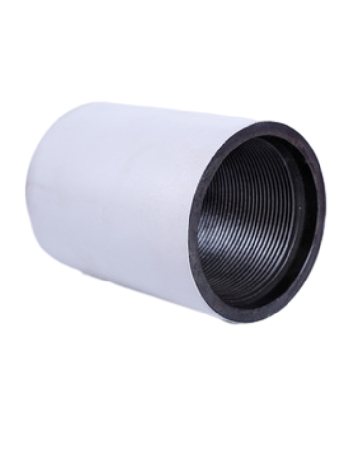

I-Tubing Coupling

Ityhubhu ukudibanisa are essential components in oil and gas production operations, facilitating the connection of two pieces of tubing. These couplings come in various shapes and sizes, ensuring a secure and leak-proof seal between tubing sections. This crucial equipment plays a vital role in maintaining the integrity of the wellbore, preventing fluid leaks and protecting the environment. Tubing couplings are often made of high-quality materials such as carbon steel, stainless steel, or alloy steel, designed to withstand high-pressure and high-temperature conditions commonly encountered in oil and gas wells. Their durability and reliability make them a preferred choice for connecting tubing strings, ensuring the smooth and efficient flow of oil and gas to the surface. In conclusion, tubing couplings are indispensable components in the oil and gas industry, playing a significant role in maintaining the safety and efficiency of production operations.

Umsonto wokudityaniswa kwetyhubhu licandelo elibalulekileyo kwishishini leoli kunye negesi, libonelela ngonxibelelwano olubalulekileyo phakathi kwamacandelo etyhubhu ukuqinisekisa ukuhamba ngokungenamthungo kwemithombo. Le misonto iyilwe ngononophelo ukuze imelane noxinzelelo oluphezulu kunye neemeko ezigqithisileyo, ezifana nezo zidibene nokugrumba elwandle okanye kwimisebenzi ye-hydraulic fracturing. Ubunjineli obuchanekileyo bemisonto yokudibanisa i-tubing ibalulekile ukuthintela ukuvuza, ukugcina imfezeko yesakhiwo, kunye nokuqinisekisa ukusebenza ngokufanelekileyo kwemithombo yeoli kunye negesi. Ngaphandle kwemisonto yokudityaniswa kwetyhubhu ethembekileyo, yonke inkqubo yotsalo iya kuba semngciphekweni wokungaphumeleli, oko kubangele ukudodobala kweendleko kunye neentlekele ezinokuthi zibe kho kokusingqongileyo. Njengoko iteknoloji iqhubela phambili, uphuhliso lwemisonto yokudibanisa iityhubhu eyomeleleyo, eyomelele ngakumbi ibalulekile ukuhlangabezana neemfuno ezikhulayo zeshishini kunye nokuqinisekisa ukukhutshwa okukhuselekileyo nokusebenzayo kwemithombo yeoli negesi.

Ukudityaniswa kweetyhubhu kudlala indima ebalulekileyo kwishishini leoli nerhasi, libonelela unxibelelwano phakathi kwamacandelo amabini etyhubhu ukuqinisekisa ukuhamba kwamanzi ngendlela engenamthungo. Ezi zidibaniso zihambelana nemigangatho ethile ebekwe ngamaqumrhu alawulayo ukuqinisekisa ukhuseleko, ukusebenza kakuhle, kunye nokuthembeka kwimisebenzi. I-American Petroleum Institute (API) iseke imilinganiselo esemgangathweni yokudibanisa iityhubhu, ichaza izinto ezinje ngeemfuno zemathiriyeli, imilinganiselo, kunye neendlela zokuvavanya ukusebenza. Ngokuthobela le migangatho, iinkampani zeoyile kunye negesi zinokuqinisekisa ukuhambelana kunye nomgangatho wokudityaniswa kweetyhubhu ezisetyenziswa kwimisebenzi yazo, ukunciphisa umngcipheko wokuvuza, ukungaphumeleli kunye nobungozi bokusingqongileyo. Ukongeza, ukudityaniswa kweetyhubhu eziqhelekileyo kuvumela ukutshintshiselana phakathi kwabavelisi abahlukeneyo, ukubonelela ngokuguquguquka kumacandelo okukhangela ngaphandle kokubeka esichengeni ukusebenza. Lilonke, ukusekwa kunye nokuthotyelwa kwemigangatho emiselweyo yokudibanisa iityhubhu kubalulekile ekugcineni imfezeko yokusebenza kunye nokhuseleko ngaphakathi kwishishini leoli negesi.