- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 14, 2025 11:21

Back to list

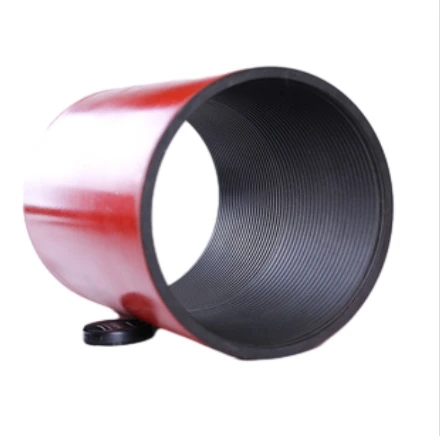

1 2 stainless steel pipe coupling

Choosing the right components for your plumbing or industrial projects can often be a daunting task, but when it comes to the 1 2 stainless steel pipe coupling, understanding its benefits and applications is key. This seemingly simple piece plays a critical role in ensuring the integrity and functionality of pipe systems in various settings. With over a decade of experience in the field, I bring you expert insights into why a high-quality stainless steel pipe coupling is an indispensable part of your materials toolkit.

In terms of expertise, working with stainless steel requires a precise understanding of the material properties and the right installation techniques. Whether it's understanding the variations in threading, sealing methods, or coupling configurations, mastery over these details ensures that the installation process is both efficient and effective. Many industry professionals aim to achieve a balance between performance and cost-efficiency when choosing their components. The 1 2 stainless steel pipe coupling unquestionably provides this balance, as its longevity reduces the need for frequent replacements and its reliability prevents costly system failures. When discussing authority, it's imperative to recognize the standards that guide stainless steel pipe production. Adhering to specifications from organizations such as ASTM International or the American Society of Mechanical Engineers ensures that products meet safety and performance requirements. High-quality manufacturers are typically certified and comply with these rigorous standards, providing added assurance of their product's reliability. Trustworthiness in this context also relates to purchasing from reputable suppliers, who provide warranties and transparent information regarding their products. As an industry best practice, ensuring that your purchase decision is informed by the provider’s technical support and product documentation is crucial. Their expertise can greatly assist in troubleshooting and optimizing system performance. To sum up, the 1 2 stainless steel pipe coupling is not just a component; it is a cornerstone that contributes to the robustness and reliability of pipe systems across numerous applications. Its resilience, coupled with its versatility and aesthetic charm, makes it a top choice for professionals who demand excellence and efficiency in their projects. By investing in high-grade stainless steel couplings, you're not just buying a part; you're securing the integrity of your entire system.

In terms of expertise, working with stainless steel requires a precise understanding of the material properties and the right installation techniques. Whether it's understanding the variations in threading, sealing methods, or coupling configurations, mastery over these details ensures that the installation process is both efficient and effective. Many industry professionals aim to achieve a balance between performance and cost-efficiency when choosing their components. The 1 2 stainless steel pipe coupling unquestionably provides this balance, as its longevity reduces the need for frequent replacements and its reliability prevents costly system failures. When discussing authority, it's imperative to recognize the standards that guide stainless steel pipe production. Adhering to specifications from organizations such as ASTM International or the American Society of Mechanical Engineers ensures that products meet safety and performance requirements. High-quality manufacturers are typically certified and comply with these rigorous standards, providing added assurance of their product's reliability. Trustworthiness in this context also relates to purchasing from reputable suppliers, who provide warranties and transparent information regarding their products. As an industry best practice, ensuring that your purchase decision is informed by the provider’s technical support and product documentation is crucial. Their expertise can greatly assist in troubleshooting and optimizing system performance. To sum up, the 1 2 stainless steel pipe coupling is not just a component; it is a cornerstone that contributes to the robustness and reliability of pipe systems across numerous applications. Its resilience, coupled with its versatility and aesthetic charm, makes it a top choice for professionals who demand excellence and efficiency in their projects. By investing in high-grade stainless steel couplings, you're not just buying a part; you're securing the integrity of your entire system.

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products