- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Innovative Applications of 1% Steel Couplings in Modern Engineering Solutions

Understanding 1% Steel Couplings A Comprehensive Overview

In the realm of mechanical engineering and construction, couplings play a pivotal role in the transfer of power between rotating shafts. They are essential components in various machinery and equipment, used to connect two shafts together for the purpose of transmitting torque while allowing for some degree of misalignment. Among the various materials used to fabricate couplings, steel is a predominant choice due to its strength, durability, and versatility. This article delves into the specifics of 1% steel couplings, exploring their composition, applications, advantages, and the considerations for their use.

Composition and Properties

The term 1% steel coupling typically refers to couplings made from steel that contains approximately 1% carbon. This type of steel is often categorized as medium carbon steel, which typically has a carbon content range between 0.3% and 0.6%. However, 1% carbon steel is considered high carbon steel, offering notably enhanced hardness and tensile strength compared to its lower carbon counterparts.

The addition of carbon in steel enhances its hardness and wear resistance, making it an ideal choice for heavy-duty applications. Steel couplings with 1% carbon content are thus particularly well-suited for environments that demand robust performance under substantial stress, such as in the automotive, aerospace, and industrial machinery sectors. Further, this composition enables the steel to undergo heat treatment processes which improve its overall mechanical properties.

Applications of 1% Steel Couplings

1% steel couplings are utilized across various industries due to their high strength and ability to withstand challenging conditions

. Some common applications include1. Industrial Machinery In manufacturing environments, machines often operate under varying loads and speeds. Steel couplings ensure that the energy transfer from one component to another remains efficient and reliable, even in dynamic conditions.

2. Automotive Engineering In vehicles, couplings are vital for connecting different parts of the drive system. High-strength couplings made from 1% steel are essential for ensuring the performance and safety of vehicles, capable of handling high torque operations.

3. Aerospace Applications In aviation engineering, weight and strength are paramount. Steel couplings are utilized in various systems, including landing gear and propulsion systems, where they must endure extreme stress without failure.

4. Pumps and Compressors In fluid handling applications, couplings must effectively transmit power while minimizing vibration and misalignment. The wear-resistant properties of high carbon steel make 1% steel couplings an ideal choice.

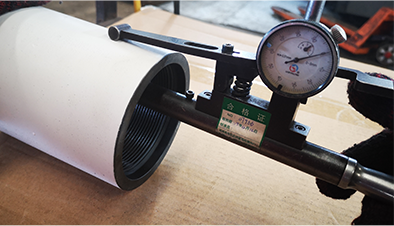

1 steel coupling

Advantages of 1% Steel Couplings

The benefits of using 1% steel couplings in various applications include

- High Strength and Durability The significant carbon content boosts the material’s mechanical properties, allowing couplings to endure high stress and fatigue over extended periods.

- Versatility These couplings can be manufactured in various designs (including rigid, flexible, and universal types) to accommodate different shaft configurations and applications.

- Ability to be Heat Treated 1% steel couplings can be subjected to heat treatment processes, enhancing their hardness, making them suitable for demanding applications in harsh environments.

- Cost-Effectiveness While carbon steel couplings may have a higher initial cost compared to some materials, their durability and performance can lead to lower maintenance and replacement costs over time.

Considerations for Use

Despite their many advantages, there are considerations to keep in mind when utilizing 1% steel couplings. Corrosion resistance is a key factor; therefore, applying protective coatings or using stainless steel alternatives may be necessary in corrosive environments. Additionally, proper alignment during installation is crucial to avoid premature wear or failure of the coupling and the connected components.

Conclusion

1% steel couplings are essential components in mechanical systems requiring reliable torque transfer and durability. With their high strength, versatility, and superior wear resistance, they meet the demanding needs of various industries, from automotive to aerospace. As engineering needs evolve, the development and refinement of materials like high carbon steel ensure that couplings continue to perform reliably in ever-challenging environments, underscoring the importance of their role in modern machinery.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025