- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 12, 2025 10:14

Back to list

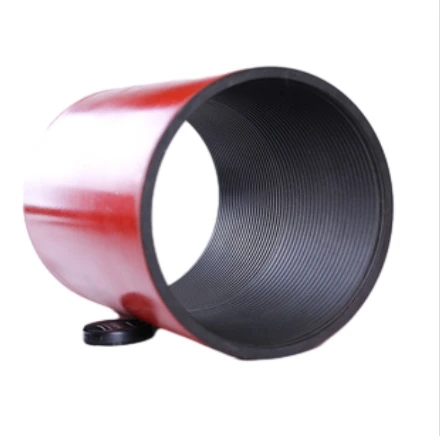

3 8 stainless steel coupling

Stainless steel couplings are a critical component in numerous industrial applications, ensuring that pipes and systems remain tightly sealed and secure. Among the various types of couplings available, the 3 8 stainless steel coupling is a standout choice for many professionals in the field. This coupling offers an unrivaled combination of durability, precision, and corrosion resistance, all of which are essential for maintaining the integrity of industrial piping systems.

When selecting a 3 8 stainless steel coupling, authority and trustworthiness of the manufacturer are also crucial considerations. Reputable manufacturers offer certifications that guarantee the quality and performance of their products. These certifications provide assurance that the couplings have been tested to withstand specific environmental and operational conditions. Additionally, established manufacturers offer warranties and robust customer support, reflecting their confidence in the durability and performance of their products. Testimonials and reviews from other industrial professionals are also valuable resources for assessing the reliability of particular coupling types before making a purchase. In practice, real-world experience further underscores the value of these couplings. Industries ranging from petrochemical to food processing rely on stainless steel for its hygienic properties and strength. Consulting with professionals who have hands-on experience with 3 8 stainless steel couplings can provide insights into their performance under different conditions, as well as advice on installation best practices. This collaborative knowledge sharing is an essential aspect of ensuring that industrial systems are not only operating smoothly but also safely and efficiently. In conclusion, the 3 8 stainless steel coupling represents a perfect blend of experience, expertise, authority, and trustworthiness, essential for robust industrial applications. Its precision, durability, and corrosion-resistant properties make it indispensable in maintaining the high standards required in challenging environments. By choosing high-quality components and collaborating with reputable manufacturers, industries can ensure both the efficiency and safety of their operations.

When selecting a 3 8 stainless steel coupling, authority and trustworthiness of the manufacturer are also crucial considerations. Reputable manufacturers offer certifications that guarantee the quality and performance of their products. These certifications provide assurance that the couplings have been tested to withstand specific environmental and operational conditions. Additionally, established manufacturers offer warranties and robust customer support, reflecting their confidence in the durability and performance of their products. Testimonials and reviews from other industrial professionals are also valuable resources for assessing the reliability of particular coupling types before making a purchase. In practice, real-world experience further underscores the value of these couplings. Industries ranging from petrochemical to food processing rely on stainless steel for its hygienic properties and strength. Consulting with professionals who have hands-on experience with 3 8 stainless steel couplings can provide insights into their performance under different conditions, as well as advice on installation best practices. This collaborative knowledge sharing is an essential aspect of ensuring that industrial systems are not only operating smoothly but also safely and efficiently. In conclusion, the 3 8 stainless steel coupling represents a perfect blend of experience, expertise, authority, and trustworthiness, essential for robust industrial applications. Its precision, durability, and corrosion-resistant properties make it indispensable in maintaining the high standards required in challenging environments. By choosing high-quality components and collaborating with reputable manufacturers, industries can ensure both the efficiency and safety of their operations.

Next:

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products