- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

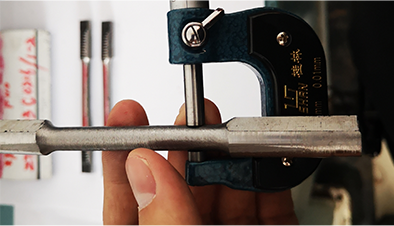

4 stainless steel coupling

Understanding 4% Stainless Steel Couplings

Stainless steel has become a cornerstone in modern engineering and construction due to its remarkable properties of corrosion resistance, strength, and versatility. Among the many applications of stainless steel, couplings, particularly those made from 4% stainless steel, are pivotal in various industries, including plumbing, oil and gas, marine, and manufacturing. This article explores the significance, applications, and benefits of 4% stainless steel couplings.

What is 4% Stainless Steel?

The term 4% stainless steel typically refers to a specific type of stainless steel alloy characterized by its composition, which includes approximately 4% nickel. This composition enhances the material's resistance to corrosion, especially in harsh environments. The presence of nickel plays a crucial role in stabilizing the austenitic structure of the steel, thereby improving its ductility and toughness.

4% stainless steel belongs particularly to the 300 series of stainless steels, known for their excellent mechanical properties and resistance to oxidation. This type of steel is particularly well-suited for applications necessitating high-performance materials that can withstand difficult conditions.

Applications of 4% Stainless Steel Couplings

Couplings are mechanical components used to connect two shafts or pipes, allowing for the transfer of torque or fluid. The use of 4% stainless steel in manufacturing these couplings offers several advantages. Some common applications include

1. Plumbing Systems In residential and commercial plumbing systems, 4% stainless steel couplings are employed to connect pipes securely. Their resistance to corrosion ensures longevity and reduces the risk of leaks.

2. Marine Industry Given its exceptional resistance to saltwater corrosion, 4% stainless steel is a popular choice for marine applications. Couplings made from this material are used to connect various components of boats and ships, ensuring durability and reliability in harsh marine environments.

3. Oil and Gas In the oil and gas industry, where equipment is exposed to extreme conditions, 4% stainless steel couplings are essential. They are used to connect pipelines and transfer fluids safely, preventing leaks that could lead to catastrophic environmental or safety issues.

4. Industrial Equipment Many manufacturers utilize 4% stainless steel couplings in machinery and production lines. The ability to withstand high temperatures and corrosive environments makes these couplings perfect for diverse industrial applications.

4 stainless steel coupling

Advantages of Using 4% Stainless Steel Couplings

The benefits of employing 4% stainless steel couplings are numerous

1. Corrosion Resistance The enhanced composition of 4% stainless steel provides impressive resistance to various types of corrosion, significantly extending the lifespan of the coupling and reducing maintenance costs.

2. Strength and Durability Couplings made from this material can endure high levels of stress and strain, making them suitable for demanding applications.

3. Versatility 4% stainless steel couplings can be manufactured in various sizes and configurations, catering to the specific needs of different industries.

4. Ease of Fabrication This type of stainless steel is relatively easy to machine and form, allowing for more complex coupling designs that can accommodate unique operational requirements.

5. Aesthetic Appeal The shiny, attractive finish of stainless steel enhances the aesthetic quality of visible installations, making it a preferred choice for both functional and decorative applications.

Conclusion

In a world that increasingly prioritizes durability and sustainability, 4% stainless steel couplings stand out as reliable components in various infrastructures. Their unique properties make them indispensable in a multitude of industries where performance, safety, and longevity are paramount.

Understanding the benefits and applications of 4% stainless steel couplings is vital for engineers, manufacturers, and contractors looking to optimize their projects and ensure efficiency. As industries evolve and seek new solutions for modern challenges, the robust performance of 4% stainless steel will undoubtedly keep it at the forefront of material choice for essential coupling applications.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025