- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

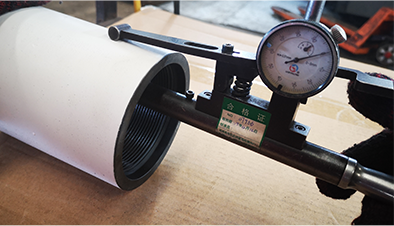

Durable 4% Stainless Steel Coupling for Reliable Connections and Enhanced Performance

The Importance and Applications of 4% Stainless Steel Couplings

In industrial and engineering contexts, the choice of materials plays a pivotal role in ensuring the reliability and efficiency of systems. One such material that has gained prominence is 4% stainless steel, notably in the manufacturing of couplings. Couplings are essential components used to connect two shafts, allowing for the transfer of torque and rotational motion while accommodating misalignments. This article explores the significance, properties, and applications of 4% stainless steel couplings.

What is 4% Stainless Steel?

The designation 4% stainless steel typically refers to a specific formulation of stainless steel that contains approximately 4% nickel, along with other alloying elements such as chromium and molybdenum. This specific composition enhances the material's overall corrosion resistance, mechanical strength, and durability, making it ideal for various applications, especially in corrosive environments.

Stainless steel is categorized into various grades, with the most common being austenitic, ferritic, martensitic, and duplex. The 4% nickel content often places it in the austenitic category, known for its face-centered cubic structure, which contributes to its excellent toughness, formability, and resistance to oxidation at elevated temperatures.

Advantages of 4% Stainless Steel Couplings

1. Corrosion Resistance One of the most significant advantages of 4% stainless steel is its exceptional resistance to corrosion. In industries that deal with harsh chemicals, moisture, or saline environments, these couplings maintain their integrity over time, reducing maintenance costs and downtime.

2. Temperature Tolerance 4% stainless steel couplings can withstand a range of temperatures, making them suitable for both high- and low-temperature applications. This versatility ensures that the couplings will function effectively in varying operational conditions, further enhancing their reliability.

3. Mechanical Strength The strength of stainless steel contributes to the durability of the couplings. They possess high tensile strength and can endure substantial loads without failure, essential for applications involving heavy machinery or equipment.

4 stainless steel coupling

4. Low Maintenance Due to its resistance to corrosion and wear, 4% stainless steel couplings require minimal maintenance. This low upkeep demand translates to reduced operational costs over time.

5. Versatile Applications The versatility of these couplings allows them to be used in numerous fields, including automotive, aerospace, marine, and industrial sectors.

Applications of 4% Stainless Steel Couplings

- Pipelines In the oil and gas industry, 4% stainless steel couplings are often used for connecting pipelines transporting corrosive substances. Their corrosion resistance ensures a longer lifespan for these critical connections.

- Food and Beverage Industry Stainless steel is widely used in food processing equipment due to its hygienic properties. Couplings made from 4% stainless steel are suitable for this industry, allowing for the safe transport of liquids and solids without contamination.

- Marine Applications Boats and ships face harsh marine environments where saltwater and humidity can cause rapid corrosion. Couplings made from 4% stainless steel provide the necessary durability and resistance to these conditions.

- Automotive Industry In vehicles, these couplings are commonly employed in the drivetrain and exhaust systems, where they must withstand high levels of stress and temperature variations.

Conclusion

4% stainless steel couplings represent a vital component in many engineering and industrial applications. Their excellent corrosion resistance, mechanical strength, low maintenance demands, and diverse applications make them an optimal choice for connecting shafts and ensuring efficient operation in various environments. As industries continue to require more robust solutions, the use of advanced materials like 4% stainless steel will undoubtedly play a significant role in future innovations and developments.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025