- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

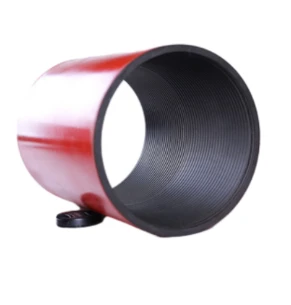

API 5CT Tubing Coupling Specifications and Applications for Oil and Gas Industry

Understanding API 5CT Tubing Couplings A Comprehensive Overview

In the oil and gas industry, the efficiency and safety of extraction processes heavily rely on the quality of the materials used in drilling and production operations. Among these materials, API 5CT tubing couplings play a crucial role in connecting segments of tubing, ensuring that fluid flows efficiently and safely from the wellbore to the surface. This article delves into the significance, specifications, and types of API 5CT tubing couplings, providing insights into their application in the oil and gas sector.

What is API 5CT?

API 5CT is a specification developed by the American Petroleum Institute (API) that outlines the requirements for casing and tubing used in wells. This specification is essential for ensuring the quality and compatibility of pipes and couplings in harsh environments. Tubing refers to the pipe used for transporting fluids from the well to the surface, and couplings are critical components that connect individual lengths of tubing. The API 5CT specification covers various steel grades, manufacturing processes, and testing requirements necessary to maintain the integrity of the connections.

Importance of Tubing Couplings

Tubing couplings serve multiple functions in a drilling operation. They are designed to connect two sections of tubing securely, allowing for the transfer of fluids while maintaining pressure integrity. A strong and reliable coupling ensures that there is no leakage of hydrocarbons during the transportation process, which could pose significant safety hazards and environmental risks. Moreover, well integrity is paramount, and tubing couplings play an essential role in preventing any communication between different zones within the well.

Specifications of API 5CT Tubing Couplings

API 5CT tubing couplings come with a range of specifications that detail their mechanical properties, dimensions, and performance characteristics

. Common specifications for tubing couplings include1. Material Grades Couplings are available in various grades, such as J55, K55, N80, C90, and P110, each designed to withstand different pressures and temperatures. The choice of grade often depends on the specific well environment and operational requirements.

api 5ct tubing coupling

2. Thread Types API 5CT tubing couplings feature various thread patterns that ensure secure connections. Common thread types include BTC (buttress thread coupling), LTC (long thread coupling), and STC (short thread coupling). The selected thread type impacts torque values and overall performance in the field.

3. Manufacturing Standards Couplings must comply with rigorous API standards to guarantee quality and safety. Manufacturers often perform various tests, such as tensile strength tests, yield tests, and non-destructive testing, to ensure that the couplings meet specified criteria.

Types of API 5CT Tubing Couplings

There are several types of API 5CT tubing couplings, categorized based on their thread design and application

- Standard Couplings These are the most common, designed for general application in oil and gas operations.

- Premium Couplings Offering enhanced properties such as superior sealing and resistance to bending, these couplings are ideal for high-pressure and high-temperature applications.

- Modified Couplings Tailored for specific needs, these couplings may include special coatings or modifications to enhance performance in corrosive environments.

Conclusion

API 5CT tubing couplings are indispensable components in the oil and gas industry that ensure safe and efficient fluid transportation from the wellbore to the surface. Their proper selection and installation are crucial for maintaining well integrity and operational efficiency. As technology evolves, advancements in coupling designs and materials will continue to enhance the safety and efficacy of drilling operations, paving the way for more sustainable and efficient hydrocarbon extraction. Understanding the nuances of API 5CT tubing couplings is essential for professionals in the industry seeking to optimize their operations and ensure compliance with established standards.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025