- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Exploring the Benefits and Applications of API Tubing Couplings in Oil and Gas Industry

The Importance of API Tubing Couplings in Oil and Gas Operations

In the oil and gas industry, the integrity and efficiency of drilling operations hinge largely on the quality of the equipment used. One critical component in this vast system is the tubing coupling, specifically those designed in accordance with the American Petroleum Institute (API) standards. These couplings play an essential role in ensuring that drilled wells operate smoothly, safely, and effectively.

API tubing couplings serve as a connection between sections of tubing, allowing for the transfer of fluids and gases from the wellbore to the surface. Their design must withstand high pressures and harsh environmental conditions while maintaining a tight seal to prevent fluid leakage. These couplings not only facilitate the flow of production but also contribute to the structural integrity of the entire drilling system.

The Importance of API Tubing Couplings in Oil and Gas Operations

Moreover, API standards establish strict guidelines for the dimensions and testing of these couplings, ensuring interchangeable compatibility and performance consistency across different manufacturers. This standardization simplifies the procurement process for operators, who can confidently select components that fit seamlessly into their existing systems without the need for extensive modifications.

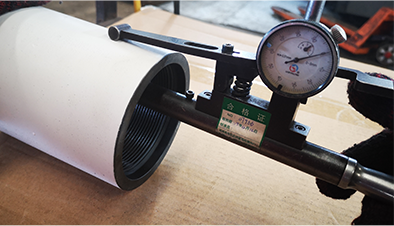

api tubing couplings

When selecting API tubing couplings, it is important for operators to consider factors such as the working pressure of the well, the type of fluid being transported, and the environmental conditions to which the equipment will be exposed. For instance, couplings used in high-pressure scenarios, such as deep-water drilling, must be rated for more stringent performance criteria compared to those used in onshore operations.

Additionally, advancements in technology have led to innovations in coupling design. Manufacturers are increasingly incorporating features such as anti-corrosion coatings and enhanced threading techniques that boost performance and ease of assembly. These improvements aim to reduce the chances of connection failures, which can lead to costly downtime and potentially dangerous blowouts.

Another critical aspect of API tubing couplings is their role in maintenance and safety protocols. Regular inspections and proper maintenance of couplings can identify potential weaknesses before they lead to catastrophic failures. By adhering to API guidelines and conducting thorough checks, operators can ensure the ongoing safety of their operations and protect the workforce and environment.

In conclusion, API tubing couplings are indispensable elements in the oil and gas industry, directly impacting the success of drilling operations. Their robust construction, adherence to established standards, and continual innovation make them vital for both operational efficiency and safety. As the industry continues to evolve, the role of these couplings will undoubtedly remain crucial in facilitating the safe and effective extraction of natural resources. By prioritizing quality and compliance with API specifications, operators can enhance their operational reliability and contribute to a safer working environment in one of the world’s most demanding industries.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025