Feb . 16, 2025 10:53

Back to list

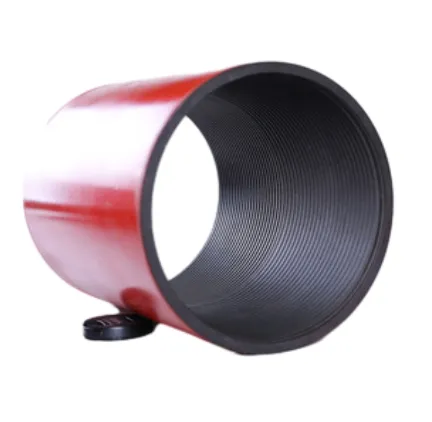

bullplugs

Understanding and Choosing the Right Bullplugs for Industrial Applications

When assessing bullplugs, it's advantageous to look for manufacturers who adhere to industry regulations and standards such as the American National Standards Institute (ANSI) and International Organization for Standardization (ISO). These standards guarantee that bullplugs meet specific safety and performance thresholds, enhancing trust and reliability in the product you choose. Moreover, advanced technology has introduced innovative features in bullplugs, such as enhanced sealing capabilities and pressure management features. Some manufacturers are integrating smart technology for real-time monitoring and assessment of plug integrity under various conditions. This enables predictive maintenance and minimized downtime, proving invaluable in high-stakes environments like offshore drilling. Investing in bullplugs that exemplify quality and reliability is also critical for businesses aiming to minimize environmental impact. Efficient bullplugs prevent leaks that can lead to environmental contamination, aligning with increasingly stringent environmental regulations and promoting sustainable industrial practices. In conclusion, understanding the nuances of bullplugs is vital for professionals across industries reliant on piping systems. By focusing on material quality, size compatibility, threading accuracy, and adherence to industry standards, you can ensure optimal performance and safety. Furthermore, embracing technological advancements in bullplug design can offer enhanced durability and monitoring capabilities, future-proofing your systems against potential failures. As a final note, building a relationship with reputable suppliers who offer a range of high-quality bullplugs will facilitate ongoing maintenance and troubleshooting. These suppliers not only provide products but also offer expertise and recommendations tailored to your specific requirements. This approach fosters a collaborative environment for sustainable and efficient industrial operations, affording peace of mind and establishing a foundation of trust in the tools and technologies that drive your business forward.

When assessing bullplugs, it's advantageous to look for manufacturers who adhere to industry regulations and standards such as the American National Standards Institute (ANSI) and International Organization for Standardization (ISO). These standards guarantee that bullplugs meet specific safety and performance thresholds, enhancing trust and reliability in the product you choose. Moreover, advanced technology has introduced innovative features in bullplugs, such as enhanced sealing capabilities and pressure management features. Some manufacturers are integrating smart technology for real-time monitoring and assessment of plug integrity under various conditions. This enables predictive maintenance and minimized downtime, proving invaluable in high-stakes environments like offshore drilling. Investing in bullplugs that exemplify quality and reliability is also critical for businesses aiming to minimize environmental impact. Efficient bullplugs prevent leaks that can lead to environmental contamination, aligning with increasingly stringent environmental regulations and promoting sustainable industrial practices. In conclusion, understanding the nuances of bullplugs is vital for professionals across industries reliant on piping systems. By focusing on material quality, size compatibility, threading accuracy, and adherence to industry standards, you can ensure optimal performance and safety. Furthermore, embracing technological advancements in bullplug design can offer enhanced durability and monitoring capabilities, future-proofing your systems against potential failures. As a final note, building a relationship with reputable suppliers who offer a range of high-quality bullplugs will facilitate ongoing maintenance and troubleshooting. These suppliers not only provide products but also offer expertise and recommendations tailored to your specific requirements. This approach fosters a collaborative environment for sustainable and efficient industrial operations, affording peace of mind and establishing a foundation of trust in the tools and technologies that drive your business forward.

Next:

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products