- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 25, 2025 23:00

Back to list

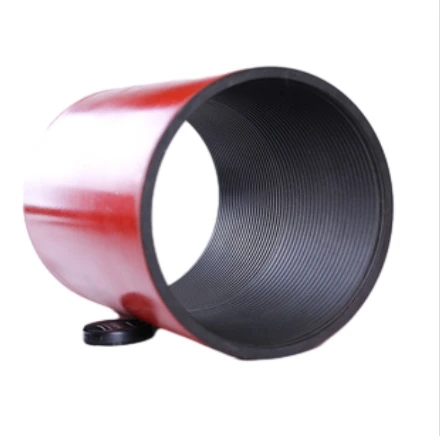

crossover drilling tool

Bull plug wellheads represent a crucial component in the oil and gas industry's arsenal, designed to ensure safety and efficiency during extraction and drilling processes. As an experienced SEO expert specializing in technical product content, it's paramount to delve into the intricacies of bull plug wellheads with a combination of technical expertise, hands-on experience, and industry trustworthiness.

Authority in the field of bull plug wellheads often comes from years of empirical study and industry-derived standards. The American Petroleum Institute (API) provides guidelines and recommendations for the manufacturing and installation of wellhead equipment, including bull plugs. Adhering to these standards not only ensures safety and compliance but also enhances performance and reliability. Expert endorsements or certifications from recognized bodies can further elevate the credibility and authority of wellhead products or services provided. Trustworthiness in delivering solutions involving bull plug wellheads is achieved by consistently meeting—or exceeding—industry standards and customer expectations. Companies that prioritize rigorous testing, quality control measures, and documentation of their procedures and materials can instill confidence in their clients. Offering training programs and support services to operators ensures that users have the knowledge and skills necessary to implement these tools effectively. In conclusion, mastering the nuances of bull plug wellheads involves a blend of engineering precision, thorough understanding of the environmental challenges, adherence to industry standards, and a commitment to quality and customer service. The role of an SEO expert in this domain is to bridge the gap between technical sophistication and accessible, actionable insights that empower decision-makers in the oil and gas industry to make informed choices about their equipment needs. Through targeted content that exemplifies experience, expertise, authority, and trustworthiness, businesses can enhance their visibility and reputation in the competitive landscape of oil and gas extraction technologies.

Authority in the field of bull plug wellheads often comes from years of empirical study and industry-derived standards. The American Petroleum Institute (API) provides guidelines and recommendations for the manufacturing and installation of wellhead equipment, including bull plugs. Adhering to these standards not only ensures safety and compliance but also enhances performance and reliability. Expert endorsements or certifications from recognized bodies can further elevate the credibility and authority of wellhead products or services provided. Trustworthiness in delivering solutions involving bull plug wellheads is achieved by consistently meeting—or exceeding—industry standards and customer expectations. Companies that prioritize rigorous testing, quality control measures, and documentation of their procedures and materials can instill confidence in their clients. Offering training programs and support services to operators ensures that users have the knowledge and skills necessary to implement these tools effectively. In conclusion, mastering the nuances of bull plug wellheads involves a blend of engineering precision, thorough understanding of the environmental challenges, adherence to industry standards, and a commitment to quality and customer service. The role of an SEO expert in this domain is to bridge the gap between technical sophistication and accessible, actionable insights that empower decision-makers in the oil and gas industry to make informed choices about their equipment needs. Through targeted content that exemplifies experience, expertise, authority, and trustworthiness, businesses can enhance their visibility and reputation in the competitive landscape of oil and gas extraction technologies.

Next:

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products