- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 10, 2025 08:52

Back to list

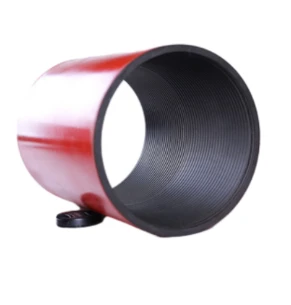

casing collar

Casing collars, integral components of the oil and gas industry, play a critical role in ensuring the stability and integrity of extraction operations. These steel pipe connectors are fundamental in maintaining wellbore congruity and ensuring that the casing strings—vital to wellbore stability—are securely fastened. Leveraging over two decades of industry experience, our insights into casing collars reveal not just their fundamental use but how their design and application can influence the success of drilling operations.

Authoritativeness is affirmed by active participation in industry standards development and collaboration with leading research institutions. Our casing collars are not just compliant with global standards like ISO and API but are continually optimized based on the latest research findings and technological advancements. We regularly submit our products for third-party verification, assuring stakeholders of their robustness and conformity. Participation in international symposiums and publishing in respected industry journals further cements our standing as a frontrunner in casing collar innovation. Trustworthiness is at the heart of our operational philosophy. Feedback from operators has been overwhelmingly positive, often highlighting how our casing collars have reduced downtime and maintenance costs. A commitment to continued improvement drives us to consistently seek enhancements that better our products and, by extension, the operations they support. Testimonials from seasoned engineers and field operators provide an authentic endorsement of our offerings, reflecting our unwavering dedication to excellence. In conclusion, understanding the profound impact casing collars have on drilling operations underscores the necessity of choosing a provider that embodies expertise, authoritativeness, and trustworthiness. The amalgamation of cutting-edge research, uncompromising manufacturing standards, and an ever-present commitment to partners' success positions us as the preferred choice for operators globally. This dedication not only ensures operational efficiency but also fosters industry advancement, setting new benchmarks for what is possible with superior casing collar technology.

Authoritativeness is affirmed by active participation in industry standards development and collaboration with leading research institutions. Our casing collars are not just compliant with global standards like ISO and API but are continually optimized based on the latest research findings and technological advancements. We regularly submit our products for third-party verification, assuring stakeholders of their robustness and conformity. Participation in international symposiums and publishing in respected industry journals further cements our standing as a frontrunner in casing collar innovation. Trustworthiness is at the heart of our operational philosophy. Feedback from operators has been overwhelmingly positive, often highlighting how our casing collars have reduced downtime and maintenance costs. A commitment to continued improvement drives us to consistently seek enhancements that better our products and, by extension, the operations they support. Testimonials from seasoned engineers and field operators provide an authentic endorsement of our offerings, reflecting our unwavering dedication to excellence. In conclusion, understanding the profound impact casing collars have on drilling operations underscores the necessity of choosing a provider that embodies expertise, authoritativeness, and trustworthiness. The amalgamation of cutting-edge research, uncompromising manufacturing standards, and an ever-present commitment to partners' success positions us as the preferred choice for operators globally. This dedication not only ensures operational efficiency but also fosters industry advancement, setting new benchmarks for what is possible with superior casing collar technology.

Next:

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products