- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 09, 2025 11:17

Back to list

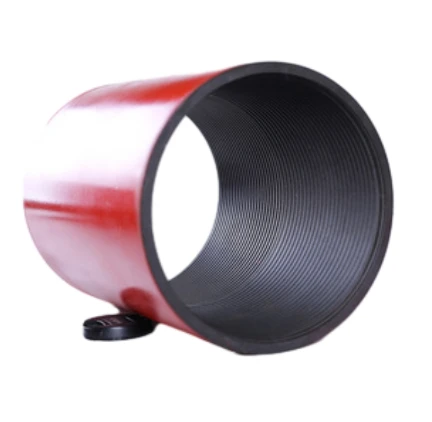

Top Casing Coupling Manufacturer in China

Choosing the right casing coupling manufacturer in China is a critical decision for companies involved in industries such as oil and gas, construction, and water well drilling. China, being a hub of manufacturing excellence, offers numerous options, but not all manufacturers deliver the same quality and reliability. Understanding the nuances involved in selecting a trustworthy casing coupling supplier can significantly impact the success of your projects and the longevity of your operations.

Authoritativeness in the market is often a byproduct of consistent quality and a solid reputation. Manufacturers held in high regard by their peers and clients typically have a history of delivering products that meet or exceed industry standards. These manufacturers often participate in international conventions and are recognized by leading industry bodies. They set the benchmarks for quality and reliability that other companies strive to meet. When a manufacturer holds authoritative status, it often indicates their proactive approach to adopting industry best practices and their ongoing commitment to research and development. Trustworthiness can be validated through certifications and client testimonials. ISO certifications, for example, are a clear indication that a manufacturer adheres to international standards in quality management, environmental responsibility, and safety. Customer feedback also provides valuable insights into the reliability and performance of the manufacturer’s products. Reviews and testimonials, particularly from long-term clients, can reveal a lot about the day-to-day interactions, product consistency, and post-purchase support offered by the manufacturer. Trustworthy manufacturers maintain transparent communication channels and ensure that clients are informed throughout the manufacturing process, promoting a strong client-manufacturer relationship. In conclusion, selecting the right casing coupling manufacturer involves a careful evaluation of their experience, expertise, authoritativeness, and trustworthiness. Manufacturers that excel in these areas not only provide high-quality products but also offer peace of mind knowing that they are reliable partners in your operational journey. By conducting thorough research and prioritizing these factors, you ensure that your choice of manufacturer supports the long-term success and efficiency of your business endeavors.

Authoritativeness in the market is often a byproduct of consistent quality and a solid reputation. Manufacturers held in high regard by their peers and clients typically have a history of delivering products that meet or exceed industry standards. These manufacturers often participate in international conventions and are recognized by leading industry bodies. They set the benchmarks for quality and reliability that other companies strive to meet. When a manufacturer holds authoritative status, it often indicates their proactive approach to adopting industry best practices and their ongoing commitment to research and development. Trustworthiness can be validated through certifications and client testimonials. ISO certifications, for example, are a clear indication that a manufacturer adheres to international standards in quality management, environmental responsibility, and safety. Customer feedback also provides valuable insights into the reliability and performance of the manufacturer’s products. Reviews and testimonials, particularly from long-term clients, can reveal a lot about the day-to-day interactions, product consistency, and post-purchase support offered by the manufacturer. Trustworthy manufacturers maintain transparent communication channels and ensure that clients are informed throughout the manufacturing process, promoting a strong client-manufacturer relationship. In conclusion, selecting the right casing coupling manufacturer involves a careful evaluation of their experience, expertise, authoritativeness, and trustworthiness. Manufacturers that excel in these areas not only provide high-quality products but also offer peace of mind knowing that they are reliable partners in your operational journey. By conducting thorough research and prioritizing these factors, you ensure that your choice of manufacturer supports the long-term success and efficiency of your business endeavors.

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products