- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

casing threads and couplings

Casing Threads and Couplings An Overview

In the oil and gas industry, the extraction of hydrocarbons deep beneath the Earth's surface is a complex process that requires sophisticated technology and equipment. One critical aspect of this process is the use of casing, which refers to the pipe that lines the wellbore and provides structural support. Integral to the construction and integrity of casing are the threads and couplings that connect individual lengths of casing pipe. Understanding these components is essential for ensuring the safe and efficient operation of drilling activities.

Casing Threads

Casing threads are specially designed grooves cut into the ends of casing pipes. These threads allow for the seamless connection between different sections of casing, ensuring that they can be securely fastened. The design of these threads is crucial; they must be robust enough to withstand the stresses of high-pressure environments.

There are several types of casing threads, commonly referred to as standard or premium threads. Standard threads are generally used for most applications and are engineered for compatibility with various types of casing. On the other hand, premium threads offer superior sealing capabilities, making them ideal for high-pressure or corrosive environments where fluid loss or leakage can be detrimental.

It's important to note that the thread design can influence not only the mechanical strength of the casing but also its ability to withstand environmental factors such as temperature fluctuations and downhole pressures. Hence, proper selection and threading techniques play a significant role in the overall success of the drilling operation.

Couplings

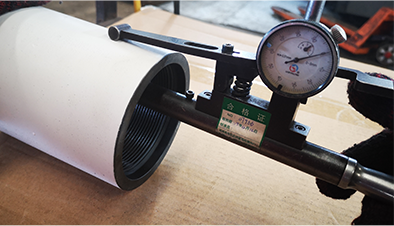

casing threads and couplings

Couplings are essential components that connect two sections of casing casing. These are typically short lengths of pipe with male and female ends featuring matching threads. Couplings provide a secure mechanical joint that enhances the structural integrity of the wellbore while allowing for some flexibility to adapt to subsurface conditions.

The use of couplings streamlines the installation process and minimizes the need for special tools, allowing for quicker assembly and disassembly. There are various types of couplings, including threaded, welded, and slip couplings, each designed for specific applications. The choice of coupling type often depends on factors such as the well depth, pressure conditions, or the type of fluid being handled.

Importance of Thread and Coupling Integrity

The integrity of casing threads and couplings is crucial for the successful operation of any drilling project. Compromised threads can lead to failures such as casing collapse or leakage, resulting in costly delays and environmental hazards. Regular inspection and maintenance of these components are necessary to ensure they meet safety standards. Advanced technologies, including non-destructive testing and thread inspection tools, are often employed to evaluate the condition of casing threads before, during, and after installation.

In addition to regular inspections, preventative measures such as the application of coatings can help limit corrosion and wear on threads over time. As the industry moves toward more environmentally-friendly practices, the development of sustainable materials and designs for casing threads and couplings is gaining traction, promising improved longevity and performance.

Conclusion

Casing threads and couplings represent critical elements in the infrastructure of oil and gas drilling. Their proper design, selection, and maintenance are paramount to ensuring the safety and efficiency of well operations. As technology evolves and the industry faces new challenges, ongoing innovation in casing design and material science will play a pivotal role in optimizing these crucial components. Understanding the intricacies of casing threads and couplings will help stakeholders make informed decisions that ensure the longevity and success of their drilling endeavors. Through continuous improvement and commitment to safety, the industry can strive for greater efficiency and environmental responsibility.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025