Mar . 04, 2025 11:04

Back to list

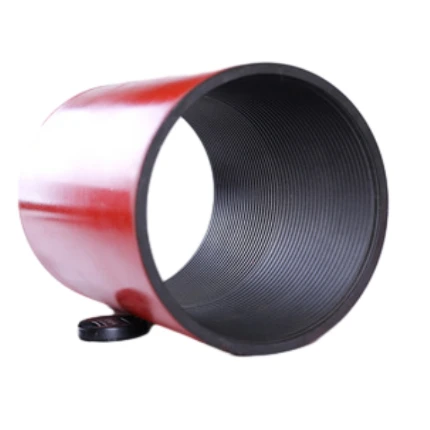

compression tubing coupler

Compression tubing couplers have revolutionized the way industries connect piping systems, providing a seamless solution for transporting fluids and gases efficiently. These couplers are indispensable in industries such as aerospace, automotive, and chemical processing, where precision and reliability are paramount. With continuous advancements in material science and engineering, choosing the right compression tubing coupler can greatly enhance the operational efficiency and safety of any system.

Expertise in the installation and maintenance of compression tubing couplers further ensures long-term reliability. Proper installation techniques involve precise alignment and torquing of the couplers, avoiding over-tightening, which can damage the fitting. Regular maintenance checks to inspect for wear and potential leakage points are indispensable practices that can drastically extend the lifespan of the couplers and reduce unforeseen downtimes. Trustworthiness in product performance is linked closely to the reputation of the manufacturer. Industry leaders invest heavily in research and development to create innovative coupler designs that meet stringent industry standards and compliance requirements. Certifications such as ISO and ASME are indicators of a manufacturer's commitment to quality and reliability. Those unfamiliar with the terrain might question the upfront cost of investing in high-quality compression tubing couplers. However, the cost-effectiveness lies in their durability, reduced maintenance needs, and the prevention of costly system failures, ultimately leading to a lower total cost of ownership. Real-world applications have repeatedly proven that the right compression tubing coupler enhances not only the immediate performance but also contributes significantly to a sustainable and efficient operational strategy. When integrity, performance, and compliance come together in one product, organizations achieve unparalleled reliability and trust in their piping systems. In conclusion, the selection of a compression tubing coupler should be made with an emphasis on expertise, authoritativeness, and trustworthiness. With the rapidly evolving industrial landscape, staying informed about the latest innovations and standards in coupling technology is imperative for maintaining competitive advantage and operational excellence. Leveraging these insights will ensure that your systems are not only functioning at peak efficiency but are also well-protected against future challenges and demands.

Expertise in the installation and maintenance of compression tubing couplers further ensures long-term reliability. Proper installation techniques involve precise alignment and torquing of the couplers, avoiding over-tightening, which can damage the fitting. Regular maintenance checks to inspect for wear and potential leakage points are indispensable practices that can drastically extend the lifespan of the couplers and reduce unforeseen downtimes. Trustworthiness in product performance is linked closely to the reputation of the manufacturer. Industry leaders invest heavily in research and development to create innovative coupler designs that meet stringent industry standards and compliance requirements. Certifications such as ISO and ASME are indicators of a manufacturer's commitment to quality and reliability. Those unfamiliar with the terrain might question the upfront cost of investing in high-quality compression tubing couplers. However, the cost-effectiveness lies in their durability, reduced maintenance needs, and the prevention of costly system failures, ultimately leading to a lower total cost of ownership. Real-world applications have repeatedly proven that the right compression tubing coupler enhances not only the immediate performance but also contributes significantly to a sustainable and efficient operational strategy. When integrity, performance, and compliance come together in one product, organizations achieve unparalleled reliability and trust in their piping systems. In conclusion, the selection of a compression tubing coupler should be made with an emphasis on expertise, authoritativeness, and trustworthiness. With the rapidly evolving industrial landscape, staying informed about the latest innovations and standards in coupling technology is imperative for maintaining competitive advantage and operational excellence. Leveraging these insights will ensure that your systems are not only functioning at peak efficiency but are also well-protected against future challenges and demands.

Next:

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products