- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Optimizing Coupling Techniques for Enhanced Tubing Performance and Reliability

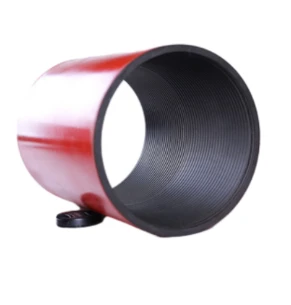

Coupling for Tubing An Essential Component in Oil and Gas Industry

In the oil and gas industry, the extraction and transportation of resources necessitate the use of various tools and machinery, among which tubings play a central role. Tubing is a critical component used to transport hydrocarbons from the wellbore to the surface. To ensure efficient and safe operation, the connections between different segments of tubing require reliable couplings. This article will delve into the functionality, types, and importance of couplings in tubing systems.

Understanding Couplings

Couplings are mechanical devices used to connect two pieces of tubing together, allowing for seamless flow and structural integrity. In the context of oil and gas extraction, couplings must withstand high pressure and corrosive substances, making their design and material selection paramount. These components not only facilitate the assembly and disassembly of tubing but also play a critical role in maintaining the overall safety and efficiency of the operations.

Types of Couplings

There are several types of couplings used in tubing, each designed for specific applications and environmental conditions. The most common types include

1. Victaulic Couplings These are grooved couplings that offer a quick and efficient method for connecting tubing segments. Their design allows for easy installation and disassembly, which can save valuable time during maintenance or repair work.

2. Threaded Couplings These traditional couplings involve screwing two tubing pieces together. While they are widely used and effective, they require precise alignment to prevent leaks and ensure strength.

3. Welded Couplings For applications where maximum strength and resistance to pressure are required, welded couplings provide a robust solution. The welding process creates a permanent bond between tubing segments, making them less prone to leaks compared to threaded couplings.

coupling for tubing

4. Flanged Couplings These utilize flanges to join two pieces of tubing. This type allows for easy access for maintenance and inspection, making them ideal for processes that require regular monitoring.

5. Split Couplings Often used in repair situations, split couplings can be installed without the need to remove the existing tubing. They provide a quick fix for leaks and extend the life of tubing in emergency situations.

Importance of Couplings in Tubing Systems

The importance of couplings in tubing systems cannot be overstated. First and foremost, they contribute to the overall safety of oil and gas operations. Poorly manufactured or improperly installed couplings can lead to leaks, which may result in catastrophic failures, environmental hazards, and financial losses. Therefore, choosing high-quality couplings designed for specific applications is crucial.

Furthermore, couplings enhance operational efficiency. They allow for easy assembly and disassembly of tubing, which is essential during maintenance, repairs, or upgrades. This efficiency translates into reduced downtime, allowing companies to maximize production and minimize costs.

Additionally, advancements in coupling technology continue to improve the reliability and performance of tubing systems. Innovations in materials science have led to the development of corrosion-resistant couplings and those designed to withstand extreme pressures. Such advancements not only bolster safety but also extend the lifespan of tubing systems, thereby reducing the need for frequent replacements.

Conclusion

In summary, couplings for tubing are vital components in the oil and gas industry, serving as the connection points that allow for efficient and safe transportation of hydrocarbons. Their variety allows for adaptability in numerous applications, while ongoing innovations promise to enhance their functionality and reliability. As the oil and gas industry continues to evolve, ensuring the integrity and safety of tubing systems through high-quality couplings will remain a top priority. Whether through threaded, welded, or flanged connections, couplings will always play a crucial role in the seamless operation of oil and gas extraction.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025