- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Durable 2-Inch Stainless Steel Couplings for Reliable Plumbing and Industrial Applications Enhancing Connectivity

Understanding 2% 20-Inch Stainless Steel Couplings

In the world of industrial components, the significance of effective coupling solutions cannot be overstated. One particular component that has garnered attention in various sectors is the 2% 20-inch stainless steel coupling. This article endeavors to explore the characteristics, advantages, applications, and maintenance of this essential mechanical component.

What is a 2% 20-Inch Stainless Steel Coupling?

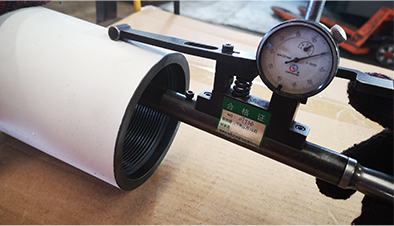

A coupling is a device used to connect two shafts together at their end for the purpose of transmitting power. The specific coupling in question—a 2% 20-inch stainless steel coupling—refers to a coupling made from stainless steel that has a nominal size of 20 inches. The 2% often pertains to the specific alloy content or the tolerance level of the material, indicating a blend that sets it apart in terms of strength and durability.

Stainless steel is preferred in many applications due to its significant corrosion resistance, strength, and durability. The addition of elements like chromium and nickel enhances these properties, making stainless steel an ideal choice for various challenging environments.

Advantages of Stainless Steel Couplings

1. Corrosion Resistance The primary advantage of stainless steel is its exceptional resistance to rust and corrosion, even in the presence of moisture or harsh chemicals. This makes the 2% 20-inch stainless steel coupling suitable for usage in industries such as oil and gas, food processing, and marine applications.

2. Strength and Durability Stainless steel’s high tensile strength ensures that the coupling can handle significant torques and misalignments, reducing the risk of failure. This durability extends the lifespan of the coupling, leading to lower replacement and maintenance costs.

3. Versatility These couplings can be utilized in various applications, whether in industrial machinery, plumbing systems, or structural connections. The ability to withstand a wide range of temperatures and pressures further enhances their applicability.

4. Ease of Maintenance Stainless steel couplings require minimal maintenance due to their resistance to wear and tear. Routine checks can ensure they function optimally without the need for extensive servicing.

Applications

The 2% 20-inch stainless steel coupling is commonly employed in several industries, thanks to its robust properties

. Here are a few notable examples2 inch stainless steel coupling

- Oil and Gas Industry In this sector, machinery is constantly exposed to harsh conditions. Stainless steel couplings are used in pipelines and drilling rigs, ensuring reliable connectivity and minimizing environmental hazards.

- Food and Beverage Industry Sanitary standards are paramount in food processing. Stainless steel couplings provide the necessary hygiene and durability, often found in conveyor belts, mixers, and other processing equipment.

- Water Treatment Facilities In water treatment, where systems might encounter corrosive substances, stainless steel couplings help ensure the integrity of the piping systems.

- Marine Applications Boats and ships often face salty and humid environments. These couplings are essential for connecting various marine components, such as pumps and engines, ensuring operational reliability.

Maintenance Tips

To ensure the longevity and effective performance of 2% 20-inch stainless steel couplings, it is important to carry out routine maintenance. Some tips include

- Regular Inspection Check for any signs of wear, misalignment, or damage regularly. Early detection can prevent further issues.

- Proper Lubrication While stainless steel has good wear resistance, appropriate lubrication can minimize friction and prolong the life of the coupling.

- Cleanliness Keeping the coupling clean from debris, dirt, and moisture will help maintain its integrity and prevent corrosion.

Conclusion

The 2% 20-inch stainless steel coupling stands as a testament to the advancements in material science, delivering reliability and efficiency across various applications. Its robust nature, combined with its resistance to corrosion and ease of maintenance, makes it a preferred choice for engineers and technicians worldwide. Proper utilization and maintenance of these couplings can lead to enhanced performance and prolonged operational life, cementing their role as essential components in modern engineering solutions.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025