Puppy Joint Specifications - High Precision, Durable Drill String Components

- Overview of especificaciones de la articulación del cachorro

and its industrial relevance - Comprehensive Technical Breakdown and Specifications

- Understanding the Perforación de la articulación del cachorro Process

- Manufacturer Comparison: Data-driven Evaluation

- Customization: Tailoring to Operational Demands

- Applications and Successful Case Studies

- Conclusion: Maximizing Efficiency through Specific Dimensiones del acoplamiento del bo?tier

(especificaciones de la articulación del cachorro)

Exploring the especificaciones de la articulación del cachorro: Critical Factors in Drilling Operations

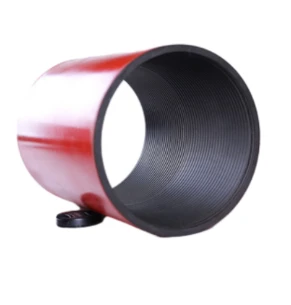

Within the oil and gas industry, especificaciones de la articulación del cachorro—also known as "pup joint specifications"—are crucial elements determining the reliability and compatibility of downhole assemblies. These components, integrating with drill strings and casing systems, serve to adjust or precisely achieve the required length, facilitate efficient thread connections, and optimize flow dynamics while reducing operational risk. Widely adopted in both onshore and offshore applications, the growing diversity of drilling environments continues to drive innovation around these specifications. This article delves into the key considerations, performance data, industry leader comparisons, bespoke solutions, and notable real-world deployments shaping modern joint specification best practices.

Technical Deep Dive: Core Specifications and Dimensional Criteria

Pup joints are designed to strict dimensional standards, often governed by API 5CT or API 5B. Key specification criteria include length (typically available in 2, 3, 4, 6, 8, 10, and 12 ft.), outside diameter (OD) compatibility, internal diameter (ID), connection type (VAM, NU, EU, premium threads), and material grade (J55, K55, L80, N80, P110, etc.). Integrity requirements extend to axial tension ratings, burst/collapse values, pressure ratings, and torque capacities. For instance, high-pressure HPHT wells may specify P110-grade with premium connections, supporting working pressures exceeding 10,000 psi and maximum torque values up to 18,000 lbf·ft.

Enhanced finishes, such as phosphate coat or glass bead blasting, reduce galling during make-up/break-out. Stringent dimensional checks ensure tolerance adherence—OD, ID, length, and thread straightness—to within ±0.015 in. Deviation could result in cumulative string misalignment, jeopardizing integrity and leading to expensive remediation or downtime.

Perforación de la articulación del cachorro: Drilling Integration and Functional Attributes

Integrating a pup joint within the drill string requires careful alignment with the string’s load, pressure, and sealing performance. The perforación de la articulación del cachorro focuses on drilling adaptation, managing fatigue stress, and reducing thread failure under cycling. Precision machining ensures thread concentricity, while shoulder designs are validated with non-destructive testing (NDT) such as magnetic particle inspection (MPI) or ultrasonic examination (UT), minimizing risk of catastrophic failure in deepwater environments.

OEMs increasingly provide field-proven metallurgy—like quench-tempered alloys—for enhanced corrosion or sour gas resilience, accompanied by drift testing, hydrostatic test certificates, and performance data. Mechanical compatibility with crossovers and adapters is confirmed by Finite Element Analysis (FEA) simulations, avoiding excessive stress localization at the joint.

Quantitative Manufacturer Benchmark: Specification and Performance Comparison

Selecting the optimal pup joint for a given application demands rigorous supplier review. Here is a data-driven comparison of leading global manufacturers based on key performance specifications, material grade, available connections, and delivery assurance:

| Manufacturer | Standard Lengths (ft.) | Material Grades | Thread Connection Options | Pressure Rating (psi) | Turnaround (weeks) |

|---|---|---|---|---|---|

| Tenaris | 2-12 | J55, K55, N80, L80, P110 | API, VAM TOP, VAM FJL | Up to 15,000 | 4-6 |

| Vallourec | 2-12 | H40, J55, L80, P110, Q125 | API, VAM ACE, VAM HT | Up to 20,000 | 7-9 |

| TMK IPSCO | 2-10 | K55, L80, N80, P110 | API, TMK PF | Up to 12,000 | 5-7 |

| OCTG Connections | 3-8 | L80, P110, CRA | API, proprietary | Up to 18,000 | 6-8 |

The comparison underlines the criticality of pressure rating, rapid fulfillment, and advanced proprietary thread offerings—impacting both cost and field performance. For unique environmental challenges, quick-access material and NDT reports further differentiate the most reliable vendors.

Customization: Engineered Solutions to Meet Complex Operations

Tailoring pup joint solutions for field-specific conditions delivers significant operational benefits. Custom options span extended or non-standard lengths (up to 20 ft.), special OD/ID transitions for tight wellbores, corrosion-resistant alloy (CRA) overlays, and heat treatments to optimize mechanical response. Laser hardfacing and advanced powder metallurgy are employed for abrasive formations.

Thread configuration can be matched to legacy systems, minimizing replacement costs and eliminating string incompatibility. API or proprietary performance enhancement features—like torque shoulder, metal-to-metal sealing, and internal/external pressure balancing—are specified to exacting well program demands. For deepwater operations, anti-vibration and high-axial load packages are increasingly requested, ensuring string longevity and minimizing NPT (non-productive time).

Applications and Field-Proven Success Stories

Pup joints play essential roles in a variety of scenarios: vertical and horizontal drilling, completions, and workover operations. In a 2022 ultradeepwater Gulf of Mexico campaign, engineered L80 pup joints in 13Cr, with proprietary metal-sealed connections, enabled 20,000 ft. casing strings with zero connector failures over a nine-month deployment. Likewise, in Middle Eastern sour gas wells, P110-grade CRA-jacketed pup joints registered 99.8% uptime across 1200 workover cycles, withstanding aggressive H₂S/CO₂ exposure. In unconventional shale, customizable OD transitions facilitated record-breaking lateral lengths, reducing stick-slip by up to 27% and yielding 12% faster run-in times.

These deployments highlight the value of aligning especificaciones de la articulación del cachorro with site-specific requirements—driving reliability, cost control, and reduced environmental impact.

Summary: Value of Precise especificaciones de la articulación del cachorro and Dimensiones del acoplamiento del bo?tier Selection

Optimizing the especificaciones de la articulación del cachorro—from perforación attributes to exact dimensiones del acoplamiento del bo?tier—translates directly into greater efficiency, longer tool life, and enhanced operational control. Advanced technical features, rigorous supplier comparison, and bespoke adaptations allow operators to minimize unplanned interventions and extend equipment service intervals. Importantly, leveraging field evidence and data-based selection ensures conformity with project goals, enhances HSE (Health, Safety, and Environment) compliance, and secures a competitive edge for both operators and EPC contractors.

(especificaciones de la articulación del cachorro)

FAQS on especificaciones de la articulación del cachorro

Q: What are the main specifications of puppy joint?

A: The main specifications of a puppy joint include its diameter, length, and thread type. These parameters ensure compatibility with drilling equipment. The material and pressure rating are also important.Q: What is meant by perforación de la articulación del cachorro (puppy joint drilling)?

A: Perforación de la articulación del cachorro refers to the process of using a puppy joint in drilling operations. It helps in adjusting the total drill string length. This provides flexibility in drilling precise depths.Q: How do you determine dimensiones del acoplamiento del boîtier (casing coupling dimensions)?

A: Casing coupling dimensions are determined by the outer diameter, length, and thread type. They must match the casing pipe specifications. Proper dimensions ensure secure and leak-proof connections.Q: Why are the specifications of a puppy joint important in drilling?

A: The specifications dictate the compatibility and performance of the puppy joint in the drill string. Proper specs prevent equipment mismatch and operational issues. This ensures safe and effective drilling.Q: Can puppy joint specifications vary between manufacturers?

A: Yes, puppy joint specifications may vary by manufacturer or according to standards used. Always consult technical datasheets or industry norms. This guarantees proper selection for your drilling project.-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025