- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

galvanized steel pipe coupling

Understanding Galvanized Steel Pipe Couplings

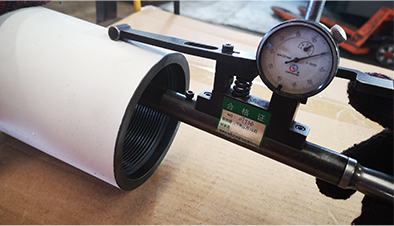

Galvanized steel pipe couplings are essential components in the plumbing and construction sectors, widely used for joining sections of steel pipes together. These couplings are made from steel that has been coated with a layer of zinc through a process called galvanization. This coating provides enhanced resistance to corrosion, thereby extending the lifespan of the pipes and ensuring their durability in various applications.

The construction of galvanized steel pipe couplings typically involves the use of either hot-dip galvanization or electro-galvanization. Hot-dip galvanization involves immersing the steel in molten zinc, resulting in a thicker coating that provides superior protection against rust and other environmental elements. On the other hand, electro-galvanization employs an electrochemical process to apply a thinner zinc coating, which is suitable for applications in less corrosive environments.

One of the significant advantages of using galvanized steel pipe couplings is their ability to withstand high pressure and temperature. This makes them ideal for industries such as oil and gas, water distribution, and HVAC systems, where reliable connections are crucial for preventing leaks and maintaining system integrity. Moreover, galvanized pipe couplings are available in various sizes and configurations, including threaded and slip-on types, to accommodate different piping requirements.

galvanized steel pipe coupling

Installation of galvanized steel pipe couplings is relatively straightforward. For threaded versions, the couplings can be easily screwed onto the ends of the pipes, while slip-on couplings require welding for a secure connection. Proper installation is paramount to ensure that the joints are tight and leak-free, which is critical for maintaining efficiency and safety in any system.

Despite their advantages, it’s important to be aware of some considerations when using galvanized steel pipe couplings. Over time, the zinc coating can wear away, exposing the underlying steel to moisture and potential corrosion. Therefore, regular inspection and maintenance are necessary to ensure the longevity of the pipes and couplings. Additionally, in environments where reactive chemicals are present, alternative materials such as stainless steel or PVC may be more appropriate due to their resistance to corrosion.

In conclusion, galvanized steel pipe couplings play a vital role in modern plumbing and construction. Their corrosion resistance, durability, and ease of installation make them a popular choice for various applications. By understanding their properties and maintenance requirements, professionals can ensure the efficiency and longevity of their piping systems. Whether in residential, commercial, or industrial settings, investing in quality galvanized steel pipe couplings is a decision that pays off in the long run, ensuring reliable performance in fluid transport and system management.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025