- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Understanding Galvanized Steel Pipe Couplings and Their Applications in Construction Projects

Understanding Galvanized Steel Pipe Couplings An Essential Guide

Galvanized steel pipe couplings are widely used components in plumbing and construction, providing a reliable connection between two lengths of pipe. Their durability, resistance to corrosion, and versatility make them an excellent choice for various applications, from residential plumbing to industrial installations. In this article, we will explore the benefits, types, applications, and installation processes of galvanized steel pipe couplings.

What is Galvanized Steel?

Before delving into couplings, it's essential to understand the material itself. Galvanized steel is steel that has been coated with a layer of zinc to protect it from corrosion and rust. This protective layer significantly extends the life of the steel, making it a popular choice for outdoor use and in environments that are prone to moisture. The galvanization process typically involves hot-dipping the steel in molten zinc or applying a zinc coating through electroplating.

Types of Galvanized Steel Pipe Couplings

Galvanized steel pipe couplings come in various types to accommodate different pipe diameters and connection styles. The most common types include

1. Coupling A straightforward component that connects two sections of pipe, allowing for a secure, leak-proof joint. Couplings are available in both threaded and slip designs.

2. Union Similar to a coupling, but with the added benefit of being removable without cutting the pipe. Unions are particularly useful in applications where future disassembly is anticipated.

3. Reducing Coupling This type of coupling is designed to connect pipes of different diameters. It allows for transitions between various pipe sizes efficiently.

4. Elbow Coupling Incorporating a bend, elbow couplings change the direction of the pipe run, commonly used in plumbing systems to navigate around obstacles.

5. Flanged Couplings These couplings feature flanges at each end for bolting two pipe sections together, providing a robust connection suitable for high-pressure applications.

Benefits of Using Galvanized Steel Pipe Couplings

1. Corrosion Resistance The zinc coating protects the steel from moisture and environmental conditions, significantly reducing the risk of rust and extending the lifespan of the pipes.

2. Strength and Durability Galvanized steel possesses high tensile strength, making it suitable for heavy-duty applications. The coupling can withstand high pressure and is resistant to mechanical damage.

galvanized steel pipe coupling

4. Versatility These couplings can be used in various applications, including water supply lines, gas lines, and industrial piping systems. They can handle different media and environmental conditions, making them invaluable in many industries.

Applications of Galvanized Steel Pipe Couplings

Galvanized steel pipe couplings find applications in numerous fields

- Plumbing and Heating Used extensively in water supply systems, hot water heating, and drainage applications, providing reliable connections that resist leaks and corrosion. - Gas Lines Ideal for natural gas and propane lines due to their strength and resistance to rust, ensuring safe and efficient gas transport.

- Construction Found in structural applications, such as scaffolding or supporting frameworks, galvanized steel pipe couplings help create robust and secure structures.

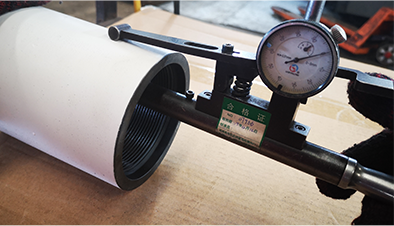

Installation of Galvanized Steel Pipe Couplings

Installing galvanized steel pipe couplings involves a few key steps to ensure a proper and leak-free connection

1. Preparation Gather all necessary tools, including wrenches, pipe cutters, and pipe thread sealant. Measure and cut pipes to the desired length.

2. Cleaning Clean the pipe ends thoroughly to remove any debris, rust, or dust, ensuring a tight fit.

3. Application of Sealant If using threaded couplings, apply a pipe thread sealant to the threads to prevent leaks.

4. Connection Screw or push the coupling onto the pipe ends, ensuring they are secure but not overly tight, which could damage the threads or coupling.

5. Testing After installation, check for leaks by running water or testing pressure through the system.

Conclusion

Galvanized steel pipe couplings are indispensable components in plumbing, construction, and industrial applications. Their corrosion resistance, strength, and versatility make them an excellent choice for both professionals and DIY enthusiasts. Understanding the different types and benefits of these couplings can help users make informed decisions, ensuring safe and effective pipe connections in any project. Whether you’re building a new home, upgrading an existing system, or undertaking industrial tasks, galvanized steel pipe couplings are an essential investment for long-lasting connections.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025