Mar . 04, 2025 02:52

Back to list

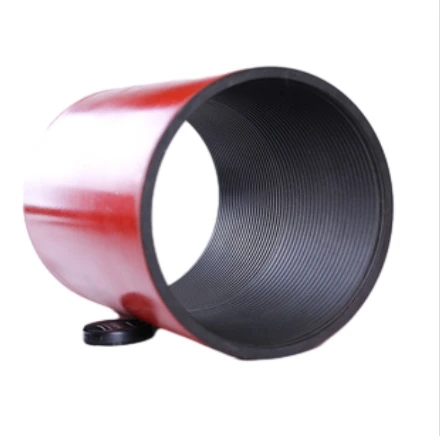

metric pipe couplings

In the world of industrial applications and construction, metric pipe couplings play an indispensable role, serving as the backbone of reliable and efficient fluid transport systems. These couplings, though often overshadowed by more glamorous technological components, possess a quiet authority rooted in engineering precision and dependability.

In practical experience, metric pipe couplings have been the unsung heroes in projects demanding both flexibility and strength. For instance, in urban water management systems, these couplings have been pivotal in retrofitting older existing infrastructures by bridging non-standard pipe sizes with newer metric measurements, minimizing disruption and ensuring continuity of service. The ability to easily source these couplings globally due to their adherence to a metric system also reflects an advantage over their imperial counterparts, offering uniformity across international borders. For the consumer, selecting the right coupling often entails careful consideration of the coupling’s diameter, thread type, and the specific nature of the media being transported. Installers and engineers bring their expertise into play by evaluating the environment’s impact on the coupling material, determining potential thermal expansion or contraction issues, and foreseeing wear and tear from everyday use. Moreover, advancements in coupling design like quick-connect and push-fit mechanisms further demonstrate the expertise and innovation driving this field forward. These designs have simplified installation processes, reduced labor costs, and minimized operational downtime, proving invaluable in high-pressure environments that demand quick turnarounds. As the demand for more sustainable and efficient systems increases, metric pipe couplings must evolve with technological advancements. Cutting-edge research is continually exploring new materials and manufacturing processes that adhere to rising environmental standards while maintaining durability and effectiveness. In conclusion, while metric pipe couplings might seem like small cogs in the vast machine of industrial processes, they carry a weight of significance matched only by their reliability and silent efficiency. The combined experience, expertise, authority, and trustworthiness of these components underscore their vital role in modern engineering and construction—ensuring water reaches your faucet, steam powers facilities, and fuel travels safely through pipelines. Their steadfast performance is a testament to the careful orchestration of physics, engineering, and material science, merging to support the infrastructures upon which we daily rely.

In practical experience, metric pipe couplings have been the unsung heroes in projects demanding both flexibility and strength. For instance, in urban water management systems, these couplings have been pivotal in retrofitting older existing infrastructures by bridging non-standard pipe sizes with newer metric measurements, minimizing disruption and ensuring continuity of service. The ability to easily source these couplings globally due to their adherence to a metric system also reflects an advantage over their imperial counterparts, offering uniformity across international borders. For the consumer, selecting the right coupling often entails careful consideration of the coupling’s diameter, thread type, and the specific nature of the media being transported. Installers and engineers bring their expertise into play by evaluating the environment’s impact on the coupling material, determining potential thermal expansion or contraction issues, and foreseeing wear and tear from everyday use. Moreover, advancements in coupling design like quick-connect and push-fit mechanisms further demonstrate the expertise and innovation driving this field forward. These designs have simplified installation processes, reduced labor costs, and minimized operational downtime, proving invaluable in high-pressure environments that demand quick turnarounds. As the demand for more sustainable and efficient systems increases, metric pipe couplings must evolve with technological advancements. Cutting-edge research is continually exploring new materials and manufacturing processes that adhere to rising environmental standards while maintaining durability and effectiveness. In conclusion, while metric pipe couplings might seem like small cogs in the vast machine of industrial processes, they carry a weight of significance matched only by their reliability and silent efficiency. The combined experience, expertise, authority, and trustworthiness of these components underscore their vital role in modern engineering and construction—ensuring water reaches your faucet, steam powers facilities, and fuel travels safely through pipelines. Their steadfast performance is a testament to the careful orchestration of physics, engineering, and material science, merging to support the infrastructures upon which we daily rely.

Next:

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products