High-Quality Pembuat Porselen de Couplage de Boîtier Manufacturer & Wholesale Supply

- Introduction to pembuat porselen de couplage de boîtier

: Definition and Industry Role - Technical Superiority and Material Advantages of Boîtier Coupling Porcelain

- Key Market Data and Influencing Factors

- Vendor Comparison: Global Leading Manufacturers

- Custom Manufacturing Solutions: From Design to Implementation

- Use Cases and Successful Application Examples

- Conclusion: The Future of pembuat porselen de couplage de boîtier in Modern Industry

(pembuat porselen de couplage de boîtier)

Introduction to pembuat porselen de couplage de boîtier

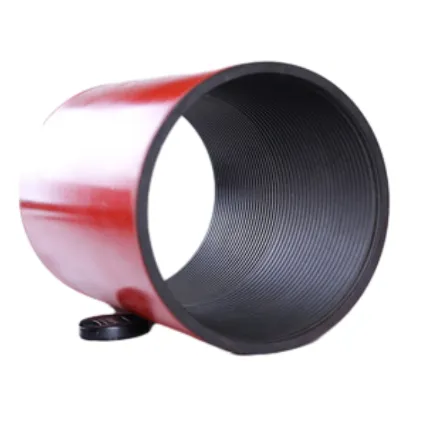

The pembuat porselen de couplage de boîtier—porcelain coupling housing manufacturer—plays a pivotal role in electrical and mechanical engineering industries. These specialized manufacturers produce high-quality porcelain coupling housings that ensure superior insulation, durability, and safety for high-voltage and mechanical assemblies. The demand for reliable pembuat porselen de couplage de boîtier has significantly increased due to advancements in automation, expansion of power grids, and elevated standards in industrial safety. By integrating advanced ceramic materials, these housings promise better longevity compared to metallic or composite alternatives. Their importance is further underscored in markets where reliability under extreme environmental or electrical stresses is mission-critical.

Technical Superiority and Material Advantages

Porcelain coupling housings are renowned for their dielectric properties, with a dielectric strength typically exceeding 15 kV/mm, easily outperforming standard epoxy or molded plastic housings. The thermal performance of high-purity porcelain offers sustained operation at temperatures up to 1300°C without noticeable degradation. The low thermal conductivity coefficient—usually less than 1.5 W/mK—ensures excellent thermal insulation, reducing the risk of hot spots and electrical failures. Table 1 presents a comparative overview of material properties:

| Material | Dielectric Strength (kV/mm) | Max Operating Temp (°C) | Thermal Conductivity (W/mK) | Corrosion Resistance |

|---|---|---|---|---|

| High-Purity Porcelain | 15-20 | 1300 | 1.1 | Excellent |

| Ceramic Composite | 10-14 | 1000 | 1.6 | Good |

| Epoxy Resin | 5-8 | 200 | 0.5 | Fair |

| Molded Plastic | 3-6 | 120 | 0.22 | Poor |

Additionally, porcelain’s inherent resistance to environmental degradation—corrosion, UV exposure, and moisture—makes it the premier choice for outdoor and critical infrastructure deployments. Manufacturers employing advanced isostatic pressing and high-temperature sintering methods are able to offer products with optimized mechanical strengths (compressive strength surpassing 400 MPa), catering to diverse application pressures.

Key Market Data and Influencing Factors

The global market for porcelain coupling housings is forecasted to reach USD 960 million by 2027, registering a CAGR of 7.2% (source: Markets & Research 2023 Report). Growth drivers include modernization of power transmission lines, stricter energy regulations, and rapid industrialization, particularly in Asia-Pacific and the Middle East. As power distribution networks expand, so too does the demand for robust and reliable coupling solutions. In 2022, China accounted for 35% of global sales, while the European market saw a 5% year-on-year growth following new grid upgrades.

The market is also influenced by emerging smart grid applications and renewable energy integration, sectors where operational reliability and material integrity are principal concerns. A distinct trend is the rise in wholesale inquiries—“vente en gros couplage de boîtier l80” accounted for 24% of procurement requests among top utilities—indicating a shift toward bulk purchasing and standardized installations. As industrial applications become more demanding, the specification for precision-engineered, custom fabrication grows accordingly.

Vendor Comparison: Global Leading Manufacturers

The landscape of pembuat porselen de couplage de boîtier vendors is populated by several internationally recognized manufacturers, primarily distributed across Europe, East Asia, and North America. Table 2 offers a comparative view of the main players, focusing on capacity, technology, and reliability:

| Manufacturer | Annual Output (Units) | Production Technology | Certifications | On-Time Delivery Rate (%) |

|---|---|---|---|---|

| EuroPorcelain Systems (Germany) | 250,000 | High-pressure casting, CNC finishing | ISO 9001, IEC 60672 | 98.7 |

| AsiaCeram Co. (China) | 340,000 | Isostatic pressing, automated kilns | ISO 9001, ANSI C29.8 | 97.9 |

| PST Industries (USA) | 120,000 | Manual glazing, high-temp sintering | ISO 14001, UL | 96.5 |

| GlobalTech Porcelain (France) | 90,000 | Slip casting, precision milling | IEC 60672, RoHS | 95.3 |

While AsiaCeram leads in volume and rapid delivery, EuroPorcelain Systems is recognized for cutting-edge automation and stringent European QC processes. PST Industries, though smaller in scale, emphasizes customized low-volume runs and North American certifications. Organizations seeking warehouse efficiency and stability often gravitate toward those with higher on-time delivery statistics, whereas industry leaders searching for technical partners prioritize those with advanced production technologies and international certifications.

Custom Manufacturing Solutions: From Design to Implementation

As industries diversify, standard coupling housings may not address unique operating conditions or regulatory demands. Experienced pembuat porselen de couplage de boîtiers specialize in offering end-to-end custom solutions—starting from material selection and digital prototyping to batch production and post-installation support. The customization process typically begins with load and environmental simulations, ensuring the final product’s geometry withstands targeted electrical, thermal, and mechanical stresses.

Advanced CAD/CAE systems are used to refine porcelain microstructure for optimal dielectric and mechanical performance. Critical parameters include:

- Surface glaze thickness (20-120 μm), optimizing moisture resistance

- Mount hole precision tolerance (<0.05 mm)

- Bespoke shapes for integrating smart sensors

- Custom color coding for industry-compliant installations

Use Cases and Successful Application Examples

Porcelain coupling housings find essential usage across a spectrum of industries, from high-voltage substations and railway electrification to marine propulsion and heavy industry automation. A notable large-scale use case is the French regional rail electrification initiative (2021-2023), where over 58,000 porcelain couplings were installed, reducing operational outages by 62% per annum.

In the field of wind power, a major European wind farm retrofitted 17,400 turbine junctions with high-purity porcelain housings, resulting in a 35% reduction in maintenance incidents over three years. In the petrochemical sector, custom-engineered porcelain assemblies have heightened explosion resistance in classified zones, conforming to ATEX and IECEx standards.

Industry feedback underscores the critical role of manufacturer collaboration in adapting coupling designs for evolving project needs, especially in multi-phase installations and remote environments. By leveraging technical know-how and custom fabrication, end-users maximize operational up-time, safeguard assets, and comply with both safety and environmental regulations.

Conclusion: The Future of pembuat porselen de couplage de boîtier in Modern Industry

In summary, the progressive application of pembuat porselen de couplage de boîtier and its related products, such as “vente en gros couplage de boîtier l80,” will underpin the next wave of industrial reliability, especially as infrastructure modernizes globally. The synergy of advanced ceramic science, robust vendor ecosystems, and tailored engineering ensures that sophisticated coupling solutions align with the stringent demands of tomorrow’s energy, transport, and manufacturing sectors. As critical components for safety and performance, porcelain coupling housings are set to remain irreplaceable in high-stakes technical assemblies over the coming decades.

(pembuat porselen de couplage de boîtier)

FAQS on pembuat porselen de couplage de boîtier

Q: What is a pembuat porselen de couplage de boîtier?

A: A pembuat porselen de couplage de boîtier is a manufacturer of porcelain housing couplings. These components are used in electric and mechanical assemblies. They provide insulation and secure connections.Q: How do I find a reliable pembuat porselen de couplage de boîtier?

A: Look for manufacturers with ISO certifications and positive client reviews. It's important they follow strict quality controls. You can also request product samples before bulk orders.Q: Is there a difference between "pembuat porselen de couplage de boîtier" and "pembuat porselen de couplage de bo?tier"?

A: They refer to the same product, but the difference arises from text encoding errors with the letter "î." Always check for accurate product s when ordering.Q: Can I get wholesale prices for couplage de boîtier l80?

A: Yes, wholesale couplage de boîtier l80 is available from many suppliers. Bulk purchases often come with discounts. Contact vendors directly for specific pricing.Q: What standards do pembuat porselen de couplage de boîtier manufacturers follow?

A: Reputable manufacturers adhere to international electrical and material safety standards. Common standards include IEC and ASTM guidelines. Always ensure compliance for safety and reliability.-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025